Corrosion behavior of TiN and TiCN coatings synthesized by PVD on the spark plasma sintered NiTi substrate

- 1 Ceramics Department, Materials and Energy Research Center (MERC), Karaj, Iran

Abstract

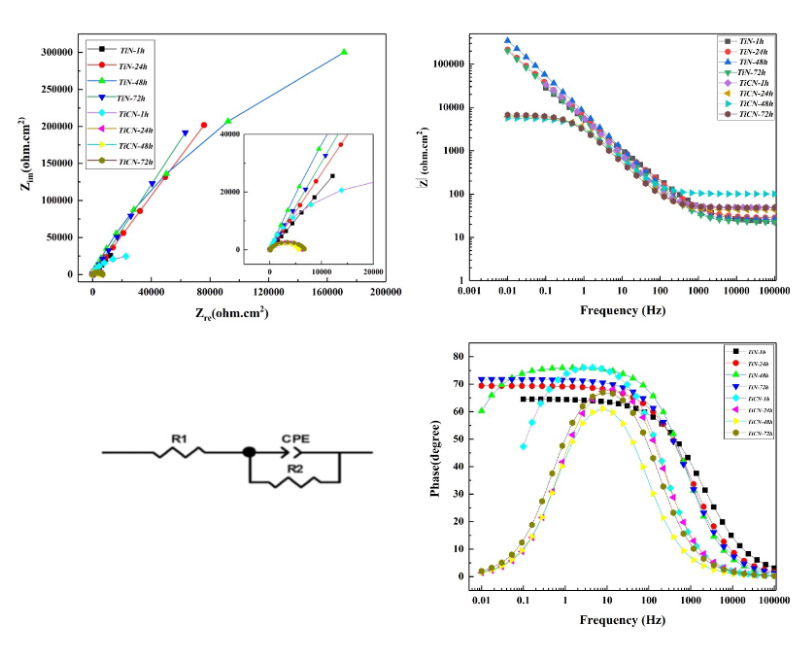

TiN and TiCN coatings have garnered widespread attentions in the field of materials science and engineering because of their exceptional characteristics, including high melting point, excellent thermal conductivity, remarkable chemical stability, superior corrosion and wear resistance, and notable biocompatibility. These properties make them highly suitable for coating various alloys, and as a result, they have been successfully applied in numerous applications. The aim of this research study is to delve into the corrosion behavior of spark plasma sintered NiTi substrates that were coated with TiN and TiCN employing physical vapor deposition (cathodic arc technology). In order to comprehensively analyze the corrosion response, potentiodynamic polarization and electrochemical impedance spectroscopy techniques were employed. To gain deeper insights into the impact of the coating, a meticulous comparison was conducted between the corrosion resistance of the uncoated specimen and that of the coated ones. The results showcased a significant enhancement in corrosion resistance for both coated samples when compared to the uncoated NiTi substrate. However, it was found that the TiN-coated specimen showed even higher corrosion resistance than the TiCN-coated counterpart. These findings highlight the superiority of TiN coatings in terms of corrosion resistance when applied on the NiTi substrate.

Downloads

References

Copyright (c) 2023 Nasim Botshekanan, Hudsa Majidian, Mohammad Farvizi

This work is licensed under a Creative Commons Attribution 4.0 International License.

Copyright

Authors are the copyright holders of their published papers in Synthesis and Sintering, which are simultaneously licensed under a Creative Commons Attribution 4.0 International License. The full details of the license are available at https://creativecommons.org/licenses/by/4.0/.

All papers published open access will be immediately and permanently free for everyone to read, download, copy, distribute, print, search, link to the full-text of papers, crawl them for indexing, pass them as data to software, or use them for any other lawful purpose without any registration obstacles or subscription fees.