Numerical optimization of sample and die geometric parameters to increase the attainable temperature during spark plasma sintering of TiC ceramics

- 1 Department of Mechanical Engineering, University of Mohaghegh Ardabili, Ardabil, Iran

- 2 Department of Mechanical Engineering, College of Engineering, Boston University, Boston, USA

Abstract

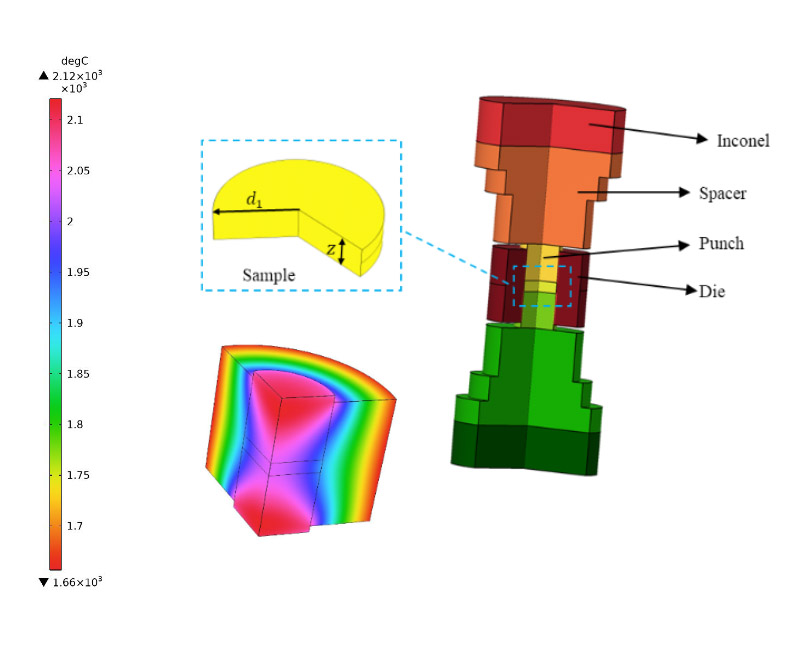

The present study offers a comprehensive thermal modeling of spark plasma sintering (SPS) for a titanium carbide (TiC) sample. Utilizing COMSOL Multiphysics Software, the research investigates the temperature distribution within the TiC sample, situated within a graphite die. The study employs governing equations for heat diffusion, augmented by terms accounting for Joule heating, to calculate temperature variations. Boundary conditions, particularly at the upper and lower limits of the system, are explicitly accounted for, with cooling mechanisms modeled as convection. Through the application of the Taguchi method and Analysis of Variance (ANOVA), the study identifies the diameter of the sintering sample as the most significant parameter affecting the maximum temperature at the center of the TiC sample, with a significance of about 87%. The outer diameter of the graphite die followed with a significance of slightly more than 10%, and the thickness of the TiC sample had a significance of around 2%. The findings contribute to a nuanced understanding of the SPS process, offering valuable insights for optimizing the sintering parameters. Numerical results further underscore the importance of specific geometric parameters in the SPS process. This study serves as a robust foundation for future research aimed at refining the SPS process for TiC samples and other materials.

Downloads

References

Copyright (c) 2023 Saeed Mohammad Bagheri, Mohsen Naderi, Mohammad Vajdi, Farhad Sadegh Moghanlou, Ali Tarlani Beris

This work is licensed under a Creative Commons Attribution 4.0 International License.

Copyright

Authors are the copyright holders of their published papers in Synthesis and Sintering, which are simultaneously licensed under a Creative Commons Attribution 4.0 International License. The full details of the license are available at https://creativecommons.org/licenses/by/4.0/.

All papers published open access will be immediately and permanently free for everyone to read, download, copy, distribute, print, search, link to the full-text of papers, crawl them for indexing, pass them as data to software, or use them for any other lawful purpose without any registration obstacles or subscription fees.