Sensitivity analysis of fluid flow parameters on the performance of fully dense ZrB2-made micro heat exchangers

- 1 Department of Mechanical Engineering, University of Mohaghegh Ardabili, Ardabil, Iran

- 2 SDU Life Cycle Engineering, Department of Green Technology, University of Southern Denmark, Campusvej 55, Odense M 5230, Denmark

Abstract

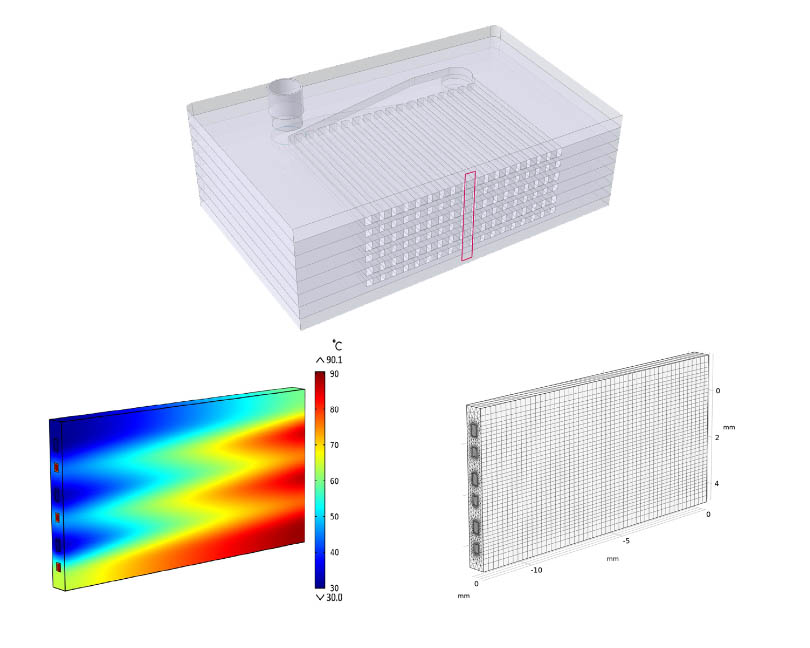

Heat exchangers are important in modern technology and are used in various industries such as power plants, automobiles and airplanes. Their main role is to ensure efficient heat transfer tailored to specific system needs. With miniaturized electronics, challenges such as circuit overheating have emerged, increasing the demand for compact yet high-performance heat exchangers. The advent of micro-electromechanical systems has increased the application of micro heat exchangers with their high surface-to-volume ratio promising enhanced efficiency. Although metals such as aluminum are commonly used for fabricating heat exchangers, their susceptibility to corrosion and high temperatures limits their usefulness. This study turns attention to ultrahigh temperature ceramics, specifically fully sintered ZrB2, known for their high temperature durability and oxidation resistance. Utilizing the Taguchi approach, a robust optimization method, this study explores the sensitivity analysis of fluid flow parameters on the performance of fully dense ZrB2-made micro heat exchangers and highlights the potential of ceramics in heat exchanger construction. Based on the results, the mass flow rate with an estimated contribution of 4.4% in the effectiveness is the most influential parameter on the performance, and in the best case, the effectiveness reaches 24.3%.

Downloads

References

Copyright (c) 2023 Mohsen Naderi, Mohammad Vajdi, Farhad Sadegh Moghanlou, Hossein Nami

This work is licensed under a Creative Commons Attribution 4.0 International License.

Copyright

Authors are the copyright holders of their published papers in Synthesis and Sintering, which are simultaneously licensed under a Creative Commons Attribution 4.0 International License. The full details of the license are available at https://creativecommons.org/licenses/by/4.0/.

All papers published open access will be immediately and permanently free for everyone to read, download, copy, distribute, print, search, link to the full-text of papers, crawl them for indexing, pass them as data to software, or use them for any other lawful purpose without any registration obstacles or subscription fees.