On the synthesis and sintering behavior of a novel Mg-Ca alloy, Part I: Mechanical alloying

- 1 Department of Materials and Metallurgical Engineering, Amirkabir University of Technology (Tehran Polytechnic), Tehran, Iran

- 2 Department of Advanced Materials and Renewable Energy, Iranian Research Organization for Science and Technology, Tehran, Iran

Abstract

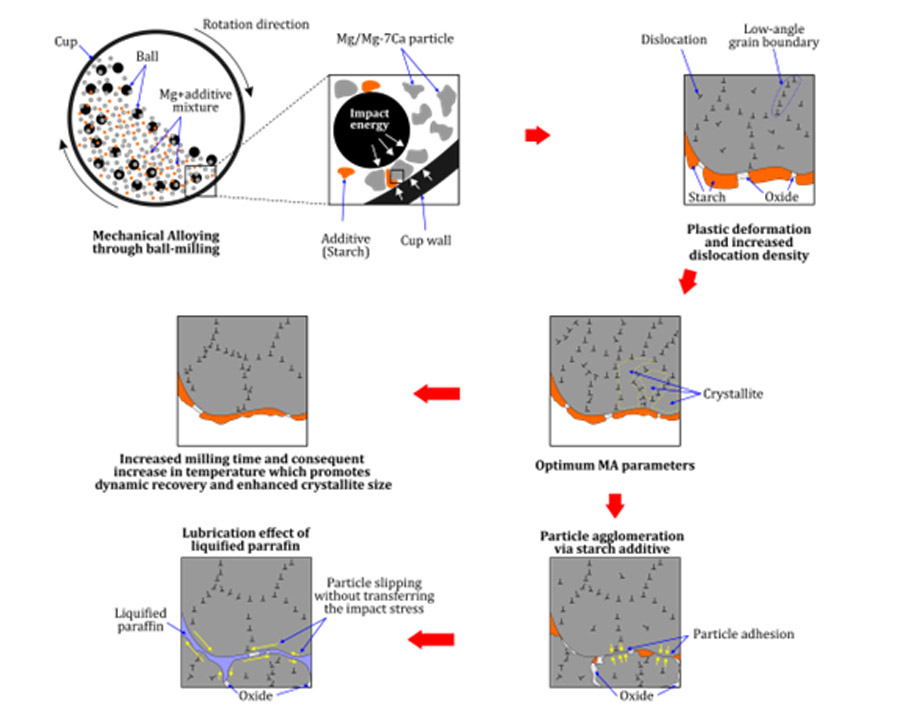

A novel Mg-0.7Ca alloy was prepared by the mechanical alloying (MA) process. Different variables were examined in order to obtain the optimum sample with the best milling behavior and potential sinterability. The structural studies were carried out using X-ray Diffractometer (XRD) and scanning electron microscopy (SEM). Crystallite size and lattice strain of the milled samples were examined by Scherrer and Williamson-Hall methods in order to finalize the investigation. The optimum milling time was found to be 60 minutes. In addition, a starch-containing sample with a fraction of 2.5 weight percent seemed to have the best microstructural properties, based on SEM observations and crystallite size assessments. Due discussions about the effective phenomena during the mechanical alloying were also included.

Downloads

References

Copyright (c) 2022 Parisa Golmohammadi, Fatemeh Saljooghi, Ahmad Bahmani, Nader Parvin, Behzad Nayebi

This work is licensed under a Creative Commons Attribution 4.0 International License.

Copyright

Authors are the copyright holders of their published papers in Synthesis and Sintering, which are simultaneously licensed under a Creative Commons Attribution 4.0 International License. The full details of the license are available at https://creativecommons.org/licenses/by/4.0/.

All papers published open access will be immediately and permanently free for everyone to read, download, copy, distribute, print, search, link to the full-text of papers, crawl them for indexing, pass them as data to software, or use them for any other lawful purpose without any registration obstacles or subscription fees.