A perspective to efficient synthesis of zirconium carbide via novel pyro-vacuum method: lower temperatures and enhanced purity

- 1 Department of Materials and Metallurgical Engineering, Amirkabir University of Technology (Tehran Polytechnic), Tehran, Iran

Abstract

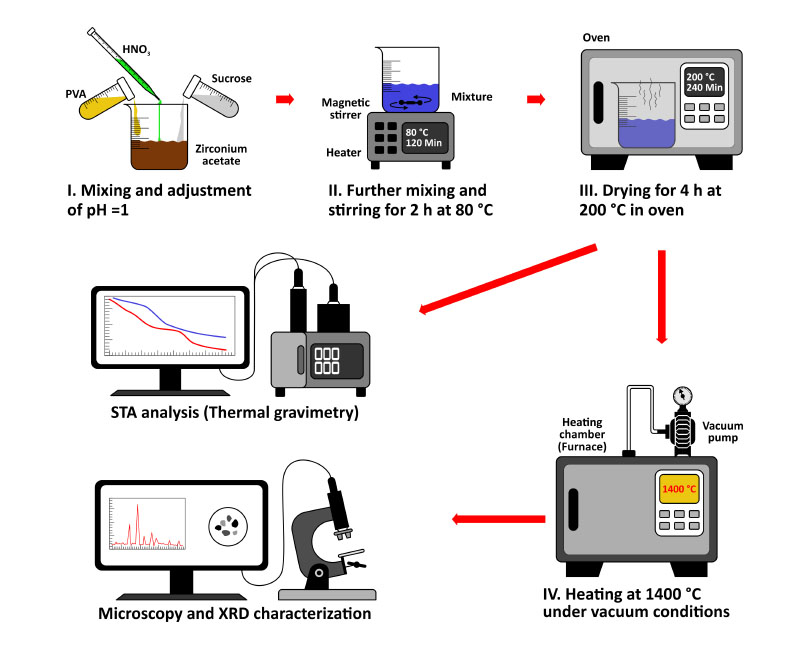

The use of ultra-high temperature ceramics (UHTCs) as a novel additive in the refractory industry is becoming increasingly popular. However, the synthesis of such materials is associated with some commercial obstacles, mainly high-temperature synthesis methods. In the present study, the pyro-vacuum method is presented as a new method to decrease the final product's synthesis temperature and oxygen content. Some thermodynamic aspects and phase evolution of the materials during the synthesis procedure are described for the synthesis of non-oxide material. Conclusively, it seems that by applying vacuum conditions, the final UHTC phases can be synthesized at significantly lower temperatures (>400 °C lower, for ZrC), if adequate powder mixtures are considered. Also due to phase analysis, it was found that the oxygen content of the final phase is lower than the conventional routes and other references. The process provides promising prospects for the economic synthesis of UHTCs.

Downloads

References

Copyright (c) 2024 Faramarz Kazemi, Behzad Nayebi

This work is licensed under a Creative Commons Attribution 4.0 International License.

Copyright

Authors are the copyright holders of their published papers in Synthesis and Sintering, which are simultaneously licensed under a Creative Commons Attribution 4.0 International License. The full details of the license are available at https://creativecommons.org/licenses/by/4.0/.

All papers published open access will be immediately and permanently free for everyone to read, download, copy, distribute, print, search, link to the full-text of papers, crawl them for indexing, pass them as data to software, or use them for any other lawful purpose without any registration obstacles or subscription fees.