On the synthesis and sintering behavior of a novel Mg-Ca alloy, Part II: Spark plasma sintering

- 1 Department of Materials and Metallurgical Engineering, Amirkabir University of Technology (Tehran Polytechnic), Tehran, Iran

- 2 Department of Advanced Materials and Renewable Energy, Iranian Research Organization for Science and Technology, Tehran, Iran

- 3 Arta Magnesium Parsian Engineering Co., Tehran, Iran

Abstract

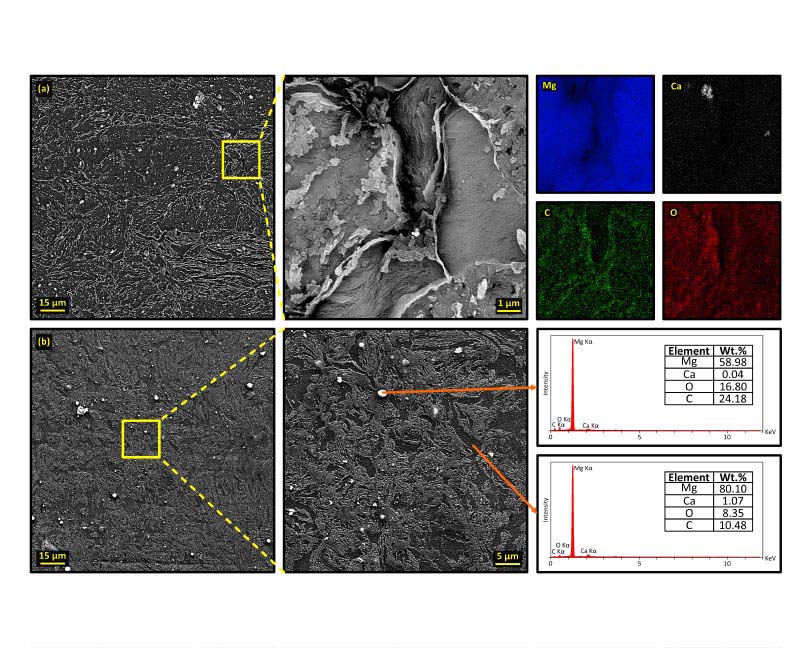

With the growing interest in lightweight materials, magnesium and its alloys have received substantial attention for replacing existing alloys. After investigating the mechanical alloying process of Mg-Ca alloys and determining the optimum parameters for milling in part I of this study, the current research aims to examine the second step: the sintering process. This study proposes the powder metallurgy method to process Mg-Ca alloy through the spark plasma sintering technique at 420 °C under an applied pressure of 38 MPa. Samples with different additives (starch or paraffin) were sintered for various dwell times (7 and 10 min) to determine the optimal mechanical and physical properties. To study the microstructure and phase composition of the sintered alloys, X-ray diffractometer (XRD), field scanning electron microscopy (FESEM), and X-ray energy dispersive spectroscopy (EDS) were utilized. Density measurement, compression test, and micro-hardness evaluation were also conducted for the physical and mechanical feathers analysis. The results indicated that samples with a dwell time of 10 min exhibited superior mechanical properties. Additionally, the starch-containing sample outperformed the paraffin-containing sample in both physical and mechanical properties.

Downloads

References

Copyright (c) 2024 Parisa Golmohammadi, Ahmad Bahmani, Nader Parvin, Behzad Nayebi

This work is licensed under a Creative Commons Attribution 4.0 International License.

Copyright

Authors are the copyright holders of their published papers in Synthesis and Sintering, which are simultaneously licensed under a Creative Commons Attribution 4.0 International License. The full details of the license are available at https://creativecommons.org/licenses/by/4.0/.

All papers published open access will be immediately and permanently free for everyone to read, download, copy, distribute, print, search, link to the full-text of papers, crawl them for indexing, pass them as data to software, or use them for any other lawful purpose without any registration obstacles or subscription fees.