Challenges toward applying UHTC-based composite coating on graphite substrate by spark plasma sintering

- 1 Ceramics Department, Materials and Energy Research Center, Karaj, Iran

Abstract

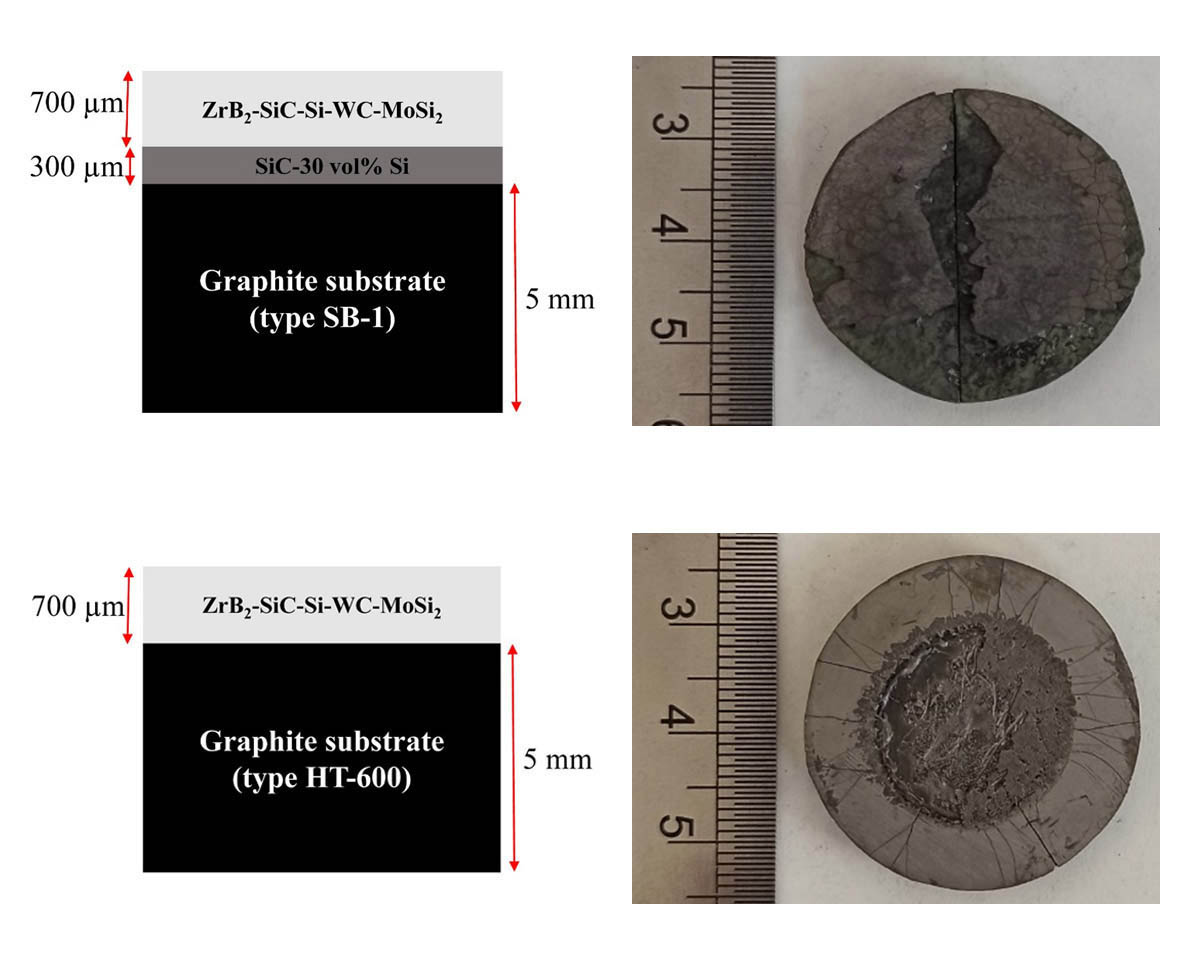

In this study, the UHTC-based composite layers where applied on the graphite substrates using SPS method to protect them against ablation. The protective layers had some defects and problems such as crack, fracture, separation, melting, and weak adhesion to the substrate. Several factors such as the thickness of composite layer, the number of protective layers, the SPS conditions (temperature, applied pressure, soaking time and mold), the chemical composition of the layers, the type of the substrate and the mismatch between the thermal expansion coefficients of the substrate and the applied layer(s) affected the quality and connection of the protective layer to the graphite substrate. The amount of additive materials influenced the melting phenomenon in the composite layer; for example, further MoSi2 in the layer led to more melting. The mismatch between the thermal expansion coefficients of the graphite substrate and the composite layer caused stresses during the cooling step, which resulted in cracks in the applied layer. Hence, proximity in the thermal expansion coefficients seems to be necessary for the formation of an acceptable adhesion between the layer and the substrate.

Downloads

References

Copyright (c) 2021 Mehran Jaberi Zamharir, Mohammad Zakeri, Mansour Razavi

This work is licensed under a Creative Commons Attribution 4.0 International License.

Copyright

Authors are the copyright holders of their published papers in Synthesis and Sintering, which are simultaneously licensed under a Creative Commons Attribution 4.0 International License. The full details of the license are available at https://creativecommons.org/licenses/by/4.0/.

All papers published open access will be immediately and permanently free for everyone to read, download, copy, distribute, print, search, link to the full-text of papers, crawl them for indexing, pass them as data to software, or use them for any other lawful purpose without any registration obstacles or subscription fees.