Ablation behavior of ZrB2–SiC–Si composites with WC and MoSi2 additives coated through SPS on graphite

- 1 Ceramics Department, Materials and Energy Research Center, Karaj, Iran

- 2 Department of Nano Technology and Advanced Materials, Materials and Energy Research Center, Karaj, Iran

- 3 Imdea Materials Institute, Calle Eric Kandel, 2, 28906, Getafe, Madrid, Spain

Abstract

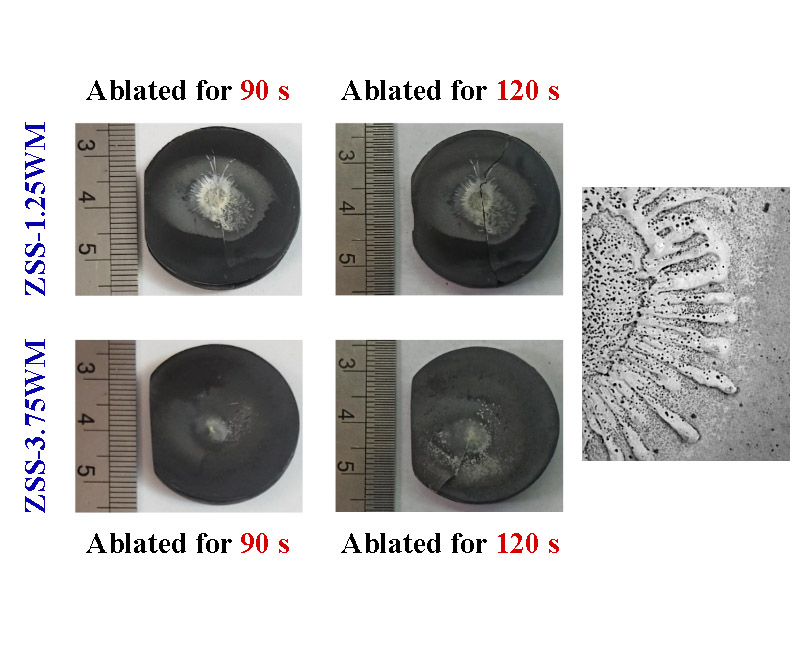

The intention of this paper is to investigate the resistance to ablation of shielding composite coatings built with ultra-high temperature ceramic materials on graphite substrate. To apply the coating on the graphite, the spark plasma sintering route was employed. The applied monolayer coatings had the base compositions of ZrB2–SiC–Si with the additives of WC and MoSi2, both in the same contents of 1.25 and 3.75 vol%. The outcomes achieved from the ablation tests by oxyacetylene flame showed that applying the protective composite coatings notably enhances the resistance to ablation of the substrate made of graphite. The coating containing more of WC and MoSi2 additives had better performance in terms of ablation resistance in 30–210 seconds. The formation of an oxide layer of (Zr,Si)O2 at the beginning of the ablation process and creating a layer with a porous microstructure on the composite coating surface functioned as a barrier against the destruction and erosion of the inner parts during longer ablation times.

Downloads

References

Copyright (c) 2023 Mehran Jaberi Zamharir, Mohammad Zakeri, Zahra Jahangiri, Ahad Mohammadzadeh

This work is licensed under a Creative Commons Attribution 4.0 International License.

Copyright

Authors are the copyright holders of their published papers in Synthesis and Sintering, which are simultaneously licensed under a Creative Commons Attribution 4.0 International License. The full details of the license are available at https://creativecommons.org/licenses/by/4.0/.

All papers published open access will be immediately and permanently free for everyone to read, download, copy, distribute, print, search, link to the full-text of papers, crawl them for indexing, pass them as data to software, or use them for any other lawful purpose without any registration obstacles or subscription fees.