Microstructural characterization of ZrB2–SiC–Si–MoSi2–WC coatings applied by SPS on graphite substrate

- 1 Ceramics Department, Materials and Energy Research Center, Karaj, Iran

- 2 Department of Nano Technology and Advanced Materials, Materials and Energy Research Center, Karaj, Iran

- 3 Imdea Materials Institute, Calle Eric Kandel, 2, 28906, Getafe, Madrid, Spain

Abstract

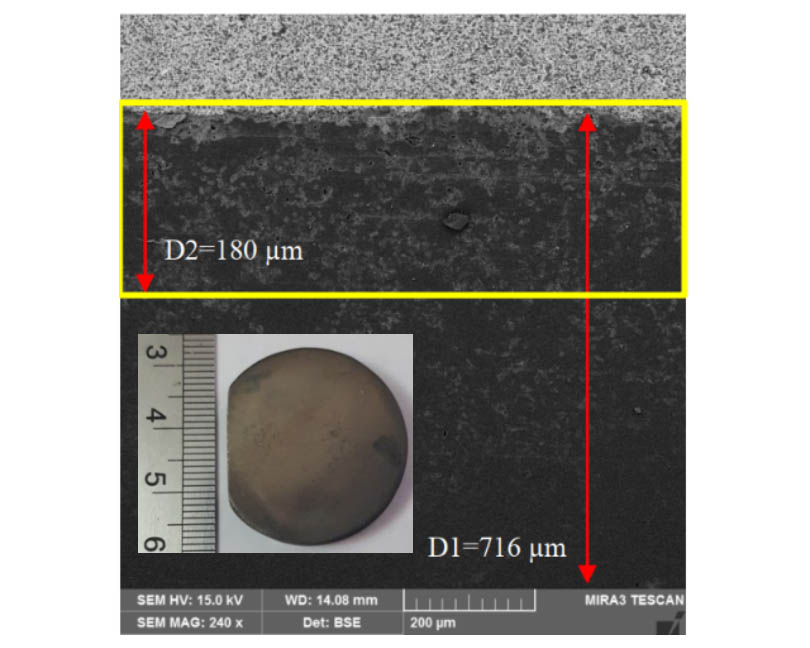

The aim of this research was to apply a protective composite coating made of ultra-high temperature ceramics (UHTCs) on the graphite substrates. The spark plasma sintering (SPS) method was used to apply this coating on the graphite substrate. First, efforts were made to choose the right chemical composition for the composite material of the coating and the sintering conditions (temperature, pressure, and holding time) for applying the coating. Then, single-layer coatings with the basic composition of ZrB2–SiC–Si with WC and MoSi2 additives in equal amounts of 1.25 and 3.75 vol% of each were successfully applied on the graphite substrates under sintering conditions of 1875±25 °C final temperature, 10 MPa initial pressure, 25 MPa final pressure and 5 min holding time. The presence of the Si element in the basic composition of these coatings, in addition to helping to form an intermediate diffusion layer at the interface between the composite coating and the graphite substrate, caused the strengthening of the joining despite the difference in the coefficient of thermal expansion between the graphite and the composite coating.

Downloads

References

Copyright (c) 2023 Mehran Jaberi Zamharir, Mohammad Zakeri, Zahra Jahangiri, Ahad Mohammadzadeh

This work is licensed under a Creative Commons Attribution 4.0 International License.

Copyright

Authors are the copyright holders of their published papers in Synthesis and Sintering, which are simultaneously licensed under a Creative Commons Attribution 4.0 International License. The full details of the license are available at https://creativecommons.org/licenses/by/4.0/.

All papers published open access will be immediately and permanently free for everyone to read, download, copy, distribute, print, search, link to the full-text of papers, crawl them for indexing, pass them as data to software, or use them for any other lawful purpose without any registration obstacles or subscription fees.