Wear behavior of self-propagating high-temperature synthesized Cu-TiO2 nanocomposites

- 1 School of Metallurgy and Materials Engineering, Iran University of Science & Technology, Narmak, Tehran, Iran

- 2 Materials Engineering Department, University of Tabriz, Tabriz, Iran

- 3 Iran Small Industries and Industrial Parks Organization (ISIPO), Tehran, Iran

- 4 Institut fur Metallurgie, TU Clausthal, Clausthal-Zellerfeld, Germany

Abstract

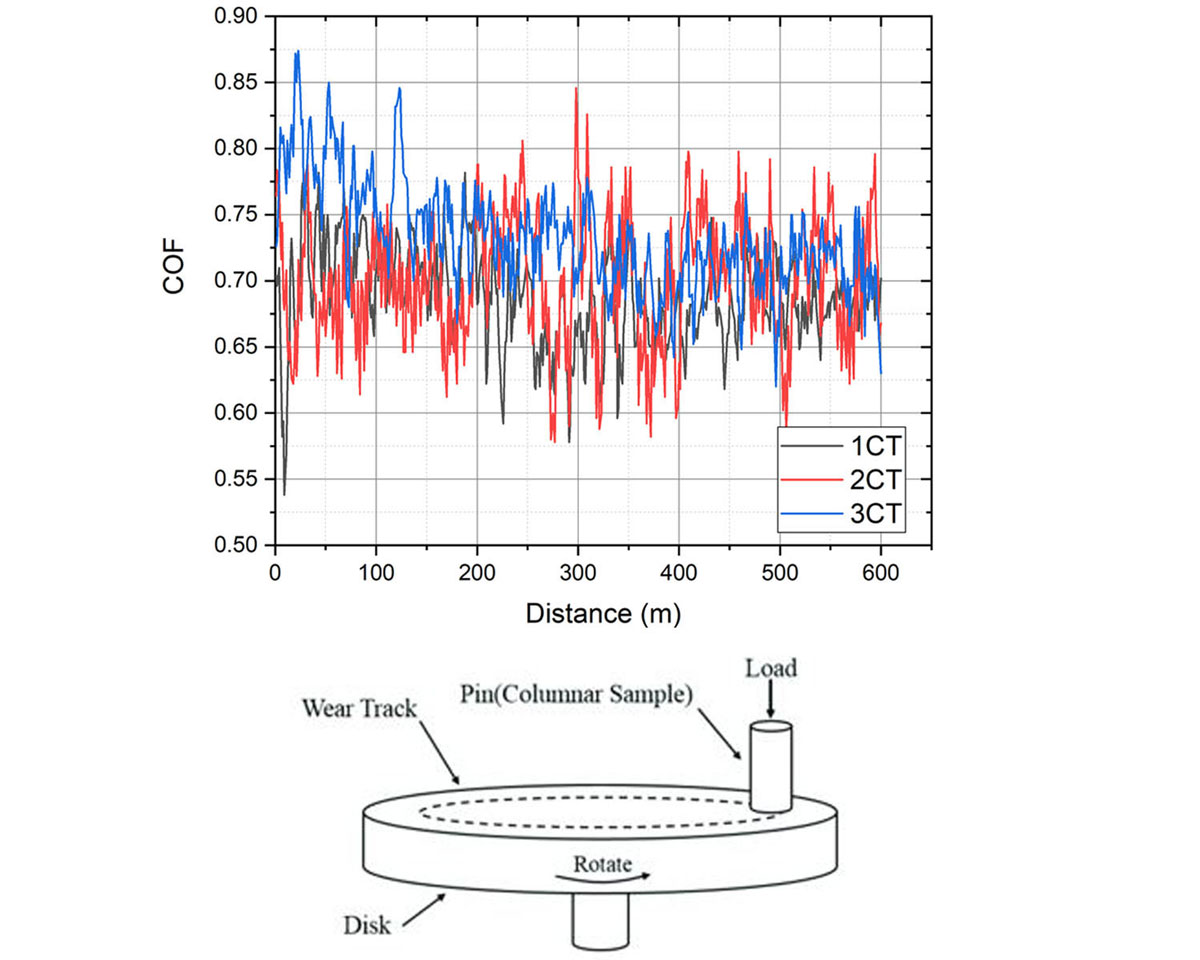

In this paper, the copper-based nanocomposites with TiO2 nanoparticles were synthesized by the self-propagating high-temperature synthesis (SHS) process. The effect of the different amounts of excess copper, in comparison with the stoichiometric ratio (CuO:Ti ratios of 1:1, 2:1, and 3:1), on the phase formation of achieved samples was studied. A thermodynamical study showed that increasing the excess copper powder reduces the adiabatic temperature, which helps the phase formation. The maximum Brinell hardness (89) was obtained for the sample with the CuO:Ti ratio of 1:1. Finally, the wear behavior of the synthesized nanocomposites was evaluated by the pin on disk test, and the variation of friction coefficient and lost weight were measured. The friction coefficient decreased by the formation of phases and distribution of titanium oxide particles during the SHS process in the presence of the stoichiometric ratio of CuO:Ti. Therefore, the wear behavior was improved. The lowest depth of wear trace was measured 0.68 where the ratio of CuO:Ti was 1:1.

Downloads

References

Copyright (c) 2021 Hossein Aghajani, Mohammad Roostaei, Shaya Sharif Javaherian, Arvin Taghizadeh Tabrizi, Ali Abdoli Silabi, Navid Farzam Mehr

This work is licensed under a Creative Commons Attribution 4.0 International License.

Copyright

Authors are the copyright holders of their published papers in Synthesis and Sintering, which are simultaneously licensed under a Creative Commons Attribution 4.0 International License. The full details of the license are available at https://creativecommons.org/licenses/by/4.0/.

All papers published open access will be immediately and permanently free for everyone to read, download, copy, distribute, print, search, link to the full-text of papers, crawl them for indexing, pass them as data to software, or use them for any other lawful purpose without any registration obstacles or subscription fees.