Recent advances in synthesis of ultra-high temperature ceramic matrix composites

- 1 Department of Chemical Engineering, University of Mohaghegh Ardabili, Ardabil, Iran

- 2 Department of Chemical Engineering, Tarbiat Modares University, Tehran, Iran

Abstract

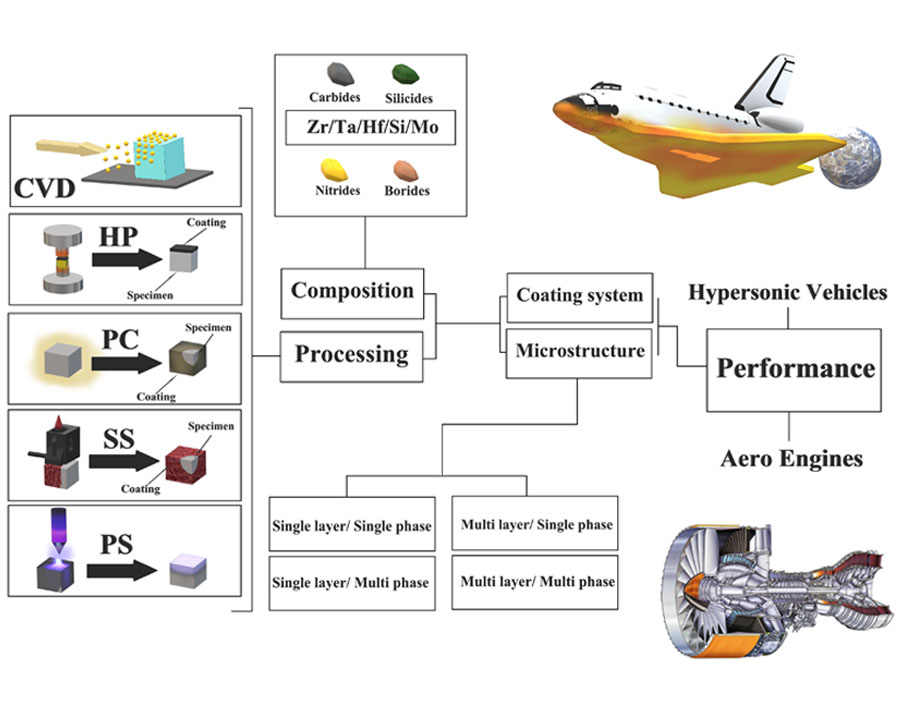

A ceramic material designed for ultra-high temperatures (UHTCs) generally comprised of nitrides, carbides, and borides derived from transition metal elements, with a particular focus on compounds belonging to TaC and Group IVB (Hf and Zr). Hypersonic vehicle nozzles and engine components can take advantage of the unique characteristics of these materials. A broad range of coatings and composites based on UHTC is currently being developed to conquer the inherent fragility, weak thermal shock resistance, and brittleness of bulk ceramics. Ultra-high temperature materials with high entropy have gained considerable attention in recent years. A review of the current state of the art of UHTC composites and coatings will be provided in this report. Properties and processing approaches to achieve the microstructure will be discussed further.

Downloads

References

Copyright (c) 2022 Farrokhfar Valizadeh Harzand, Sahar Anzani, Aziz Babapoor

This work is licensed under a Creative Commons Attribution 4.0 International License.

Copyright

Authors are the copyright holders of their published papers in Synthesis and Sintering, which are simultaneously licensed under a Creative Commons Attribution 4.0 International License. The full details of the license are available at https://creativecommons.org/licenses/by/4.0/.

All papers published open access will be immediately and permanently free for everyone to read, download, copy, distribute, print, search, link to the full-text of papers, crawl them for indexing, pass them as data to software, or use them for any other lawful purpose without any registration obstacles or subscription fees.