Recent advances in synthesis and applications of mixed matrix membranes

- 1 Department of Chemical Engineering, Science and Research Branch, Islamic Azad University, Tehran, Iran

- 2 School of Mechanical Engineering, University of Adelaide, Adelaide, Australia

- 3 Department of Chemical Engineering, University of Mohaghegh Ardabili, Ardabil, Iran

Abstract

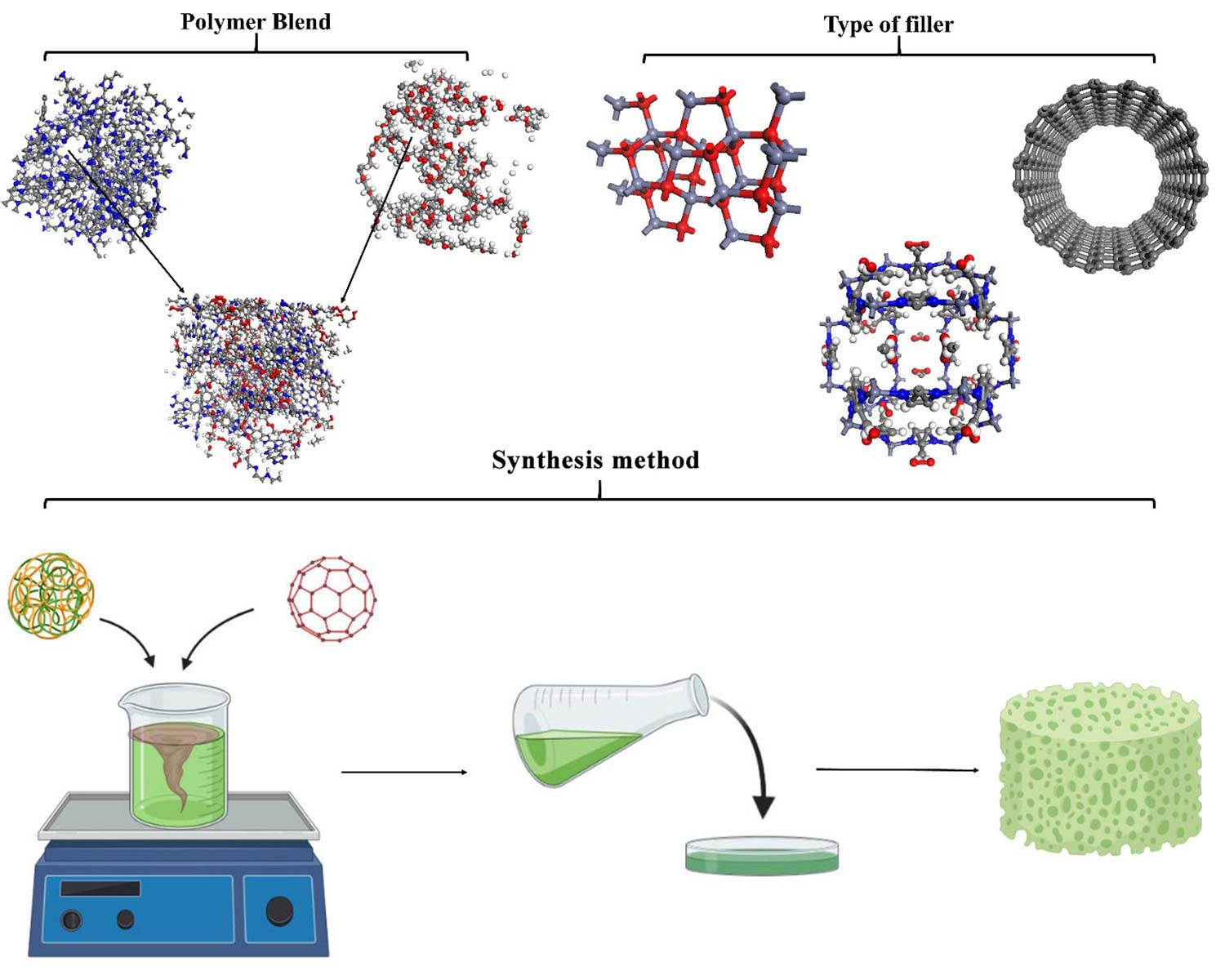

Researchers are currently considering membranes separation processes due to their eco-friendly, process simplicity and high efficiency. Selecting a suitable and efficient operation is the primary concern of researchers in the field of separation industries. In recent decades, polymeric and inorganic membranes in the separation industry have made significant progress. The polymeric and inorganic membranes have been challenged due to their competitiveness in permeability and selectivity factors. A combination of nanoparticle fillers within the polymer matrix is an effective method to increase polymeric and inorganic membranes’ efficiency in separation processes. Mixed matrix membranes (MMMs) have been considered by the separation industry due to high mechanical and physicochemical, and transfer properties. Moreover, gas separation, oil treatment, heavy metal ions removal, water treatment and oil-water separation are common MMMs applications. Selecting suitable polymer blends and fillers is the key to the MMMs construction. The combination of rubbery and glassy polymers with close solubility parameters increases the MMMs performance. The filler type and synthesis methods also affect the morphological and transfer properties of MMMs significantly. Zeolites, graphene oxide (GO), nanosilica, carbon nanotubes (CNTs), zeolite imidazole frameworks (ZIFs) and metal-organic frameworks (MOFs) are used in the MMMs synthesis as fillers. Finally, solution mixing, polymerization in situ and sol-gel are the primary synthesising MMMs methods.

Downloads

References

Copyright (c) 2021 Iman Salahshoori, Ahmad Seyfaee, Aziz Babapoor

This work is licensed under a Creative Commons Attribution 4.0 International License.

Copyright

Authors are the copyright holders of their published papers in Synthesis and Sintering, which are simultaneously licensed under a Creative Commons Attribution 4.0 International License. The full details of the license are available at https://creativecommons.org/licenses/by/4.0/.

All papers published open access will be immediately and permanently free for everyone to read, download, copy, distribute, print, search, link to the full-text of papers, crawl them for indexing, pass them as data to software, or use them for any other lawful purpose without any registration obstacles or subscription fees.