Sintered transparent polycrystalline ceramics: the next generation of fillers for clarity enhancement in corundum

- 1 Department of Metallurgical and Materials Engineering, Istanbul Technical University, Maslak 34467, Istanbul, Turkey

- 2 GemLab, Bangkok 10120, Thailand

Abstract

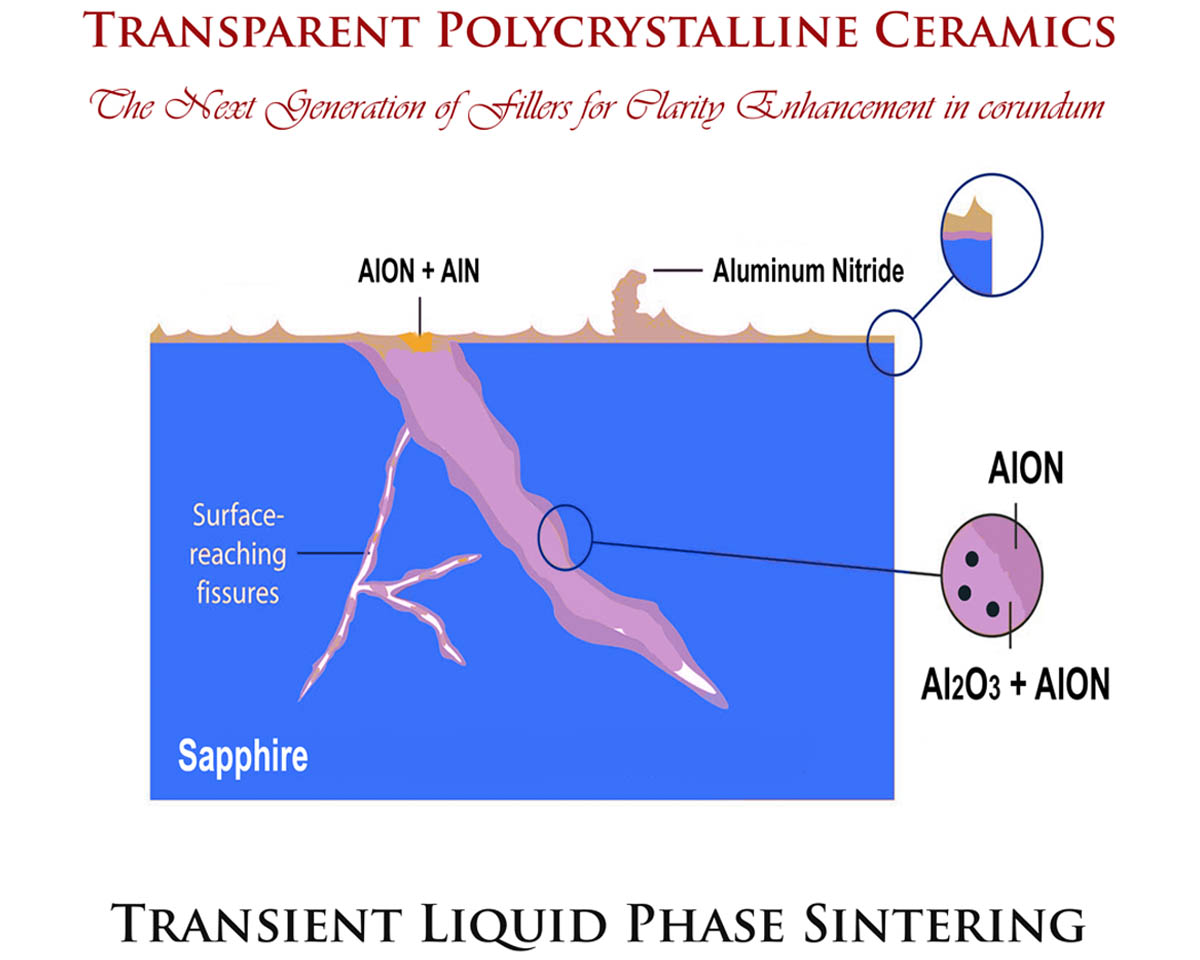

A significant proportion of mined natural corundum (ruby and sapphire) contain fractures, which negatively affect a gemstone’s clarity and value. Over the past decades, heat treatment techniques have been developed for either fracture healing or filling to make such gems marketable. The clarity enhancement processes are mainly based on techniques which are either not durable, as in the case of lead silicate fillers, or do not yield perfect transmittance through a fracture, as in the case of borax based fluxes. Therefore, the gemstone treatment community is actively in pursuit of better techniques for clarity enhancement in corundum. Given that application of pressure is a recent advancement in the heat treatment processes of natural sapphire, it is essential to explore the possibilities regarding different outcomes such treatments can have. In this perspective paper, we have briefly described how the application of pressure during heat treatments can lead to in-situ sintering of transparent polycrystalline ceramics within the fractures of corundum, which can result in clarity enhancement. Spinel-structure based fillers can be tailored to mimic corundum in terms of tribological, chemical, and optical properties. Therefore, gemstones treated with such fillers will be durable, unlike currently used glass-based filler material. We also provide a possible explanation for ghost-fissures in sapphires heated under pressure, as being a by-product of an in-situ sintering process of ceramic fillers that are thermodynamically compatible with Al2O3. The prospect of transparent polycrystalline ceramics in the gem and jewelry industry opens a new field of research in this area, given that ceramic fillers can outperform currently used methods and materials for clarity enhancement in gemstones. In essence, we present a novel application for sintered transparent polycrystalline ceramics.

Downloads

References

Copyright (c) 2021 Mubashir Mansoor, Mehya Mansoor, Maryam Mansoor, Ted Themelis, Filiz Çinar Şahin

This work is licensed under a Creative Commons Attribution 4.0 International License.

Copyright

Authors are the copyright holders of their published papers in Synthesis and Sintering, which are simultaneously licensed under a Creative Commons Attribution 4.0 International License. The full details of the license are available at https://creativecommons.org/licenses/by/4.0/.

All papers published open access will be immediately and permanently free for everyone to read, download, copy, distribute, print, search, link to the full-text of papers, crawl them for indexing, pass them as data to software, or use them for any other lawful purpose without any registration obstacles or subscription fees.