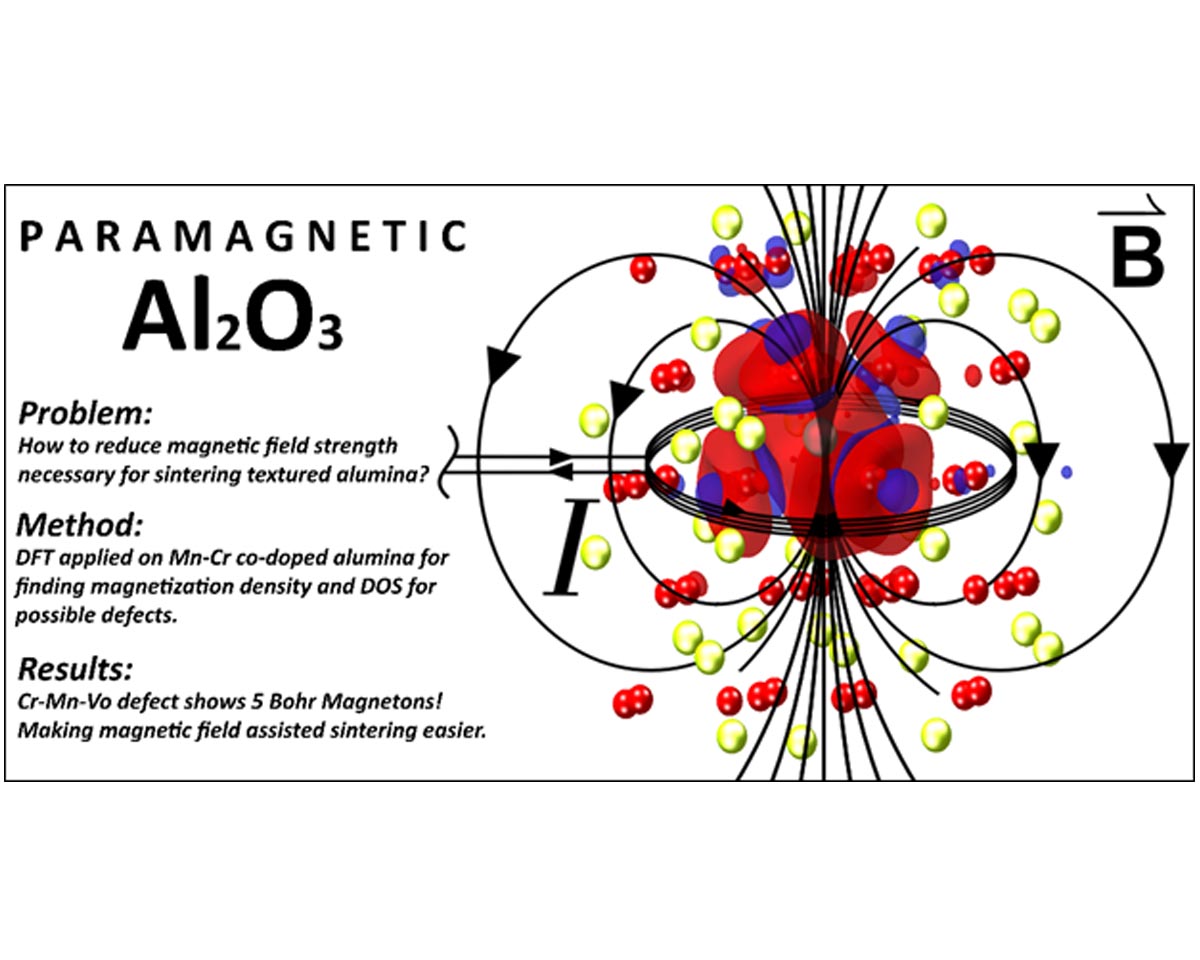

Ab-initio study of paramagnetic defects in Mn and Cr doped transparent polycrystalline Al2O3 ceramics

- 1 Department of Metallurgical and Materials Engineering, Istanbul Technical University, Maslak 34467, Istanbul, Turkey

- 2 Department of Applied Physics, Istanbul Technical University, Maslak 34467, Istanbul, Turkey

Abstract

Birefringence is a major source of difficulty in sintering of transparent polycrystalline alumina ceramics, especially as the grain size exceeds a few hundred nanometers, which ultimately leads to complete opacity, mainly due to scattering of light. Recent studies have made it clear that by application of a strong magnetic field, alumina grains can be aligned along a particular crystallographic orientation, which minimizes scattering due to birefringence, and enhances transparency. Defects that cause spin delocalization are known to induce a paramagnetic behavior in alumina ceramics. Therefore, such defects have become a focal point of research for magnetic field assisted sintering of transparent polycrystalline alumina, in order to reduce the necessary magnetic field strength during production process. In light of recent studies on paramagnetic potentials of transition metal doped alumina, we have applied Spin Polarized Density Functional Theory (SP-DFT) calculations on manganese and chromium doped and co-doped alumina to calculate the magnetic moments, density of states and defect formation energies, which should be expected from this system of dopants, along with their interactions with oxygen vacancies. The results clearly indicate that formation of a point defect comprised of chromium and manganese positioned substitutionally at adjacent aluminum sites, in vicinity of an oxygen vacancy can induce a magnetic moment equivalent to 5 Bohr magnetons (μβ), outperforming previously reported defects. Based on this study we find it likely that chromium and manganese co-doping in alumina can further reduce the required magnetic field strength for production of transparent polycrystalline alumina.

Downloads

References

Copyright (c) 2021 Mubashir Mansoor, Mehya Mansoor, Maryam Mansoor, Zuhal Er, Filiz Çinar Şahin

This work is licensed under a Creative Commons Attribution 4.0 International License.

Copyright

Authors are the copyright holders of their published papers in Synthesis and Sintering, which are simultaneously licensed under a Creative Commons Attribution 4.0 International License. The full details of the license are available at https://creativecommons.org/licenses/by/4.0/.

All papers published open access will be immediately and permanently free for everyone to read, download, copy, distribute, print, search, link to the full-text of papers, crawl them for indexing, pass them as data to software, or use them for any other lawful purpose without any registration obstacles or subscription fees.