Pressureless sinterability study of ZrB2–SiC composites containing hexagonal BN and phenolic resin additives

- 1 Department of Engineering & Technology, Southeast Missouri State University, Cape Girardeau, MO 63701, USA

- 2 Department of Chemistry and Drug Technologies, Sapienza University of Rome, P.le Aldo Moro 5, 00185 Rome, Italy

- 3 Department of Materials Science and Engineering, Research Institute of Advanced Materials, Seoul National University, Seoul 08826, Republic of Korea

Abstract

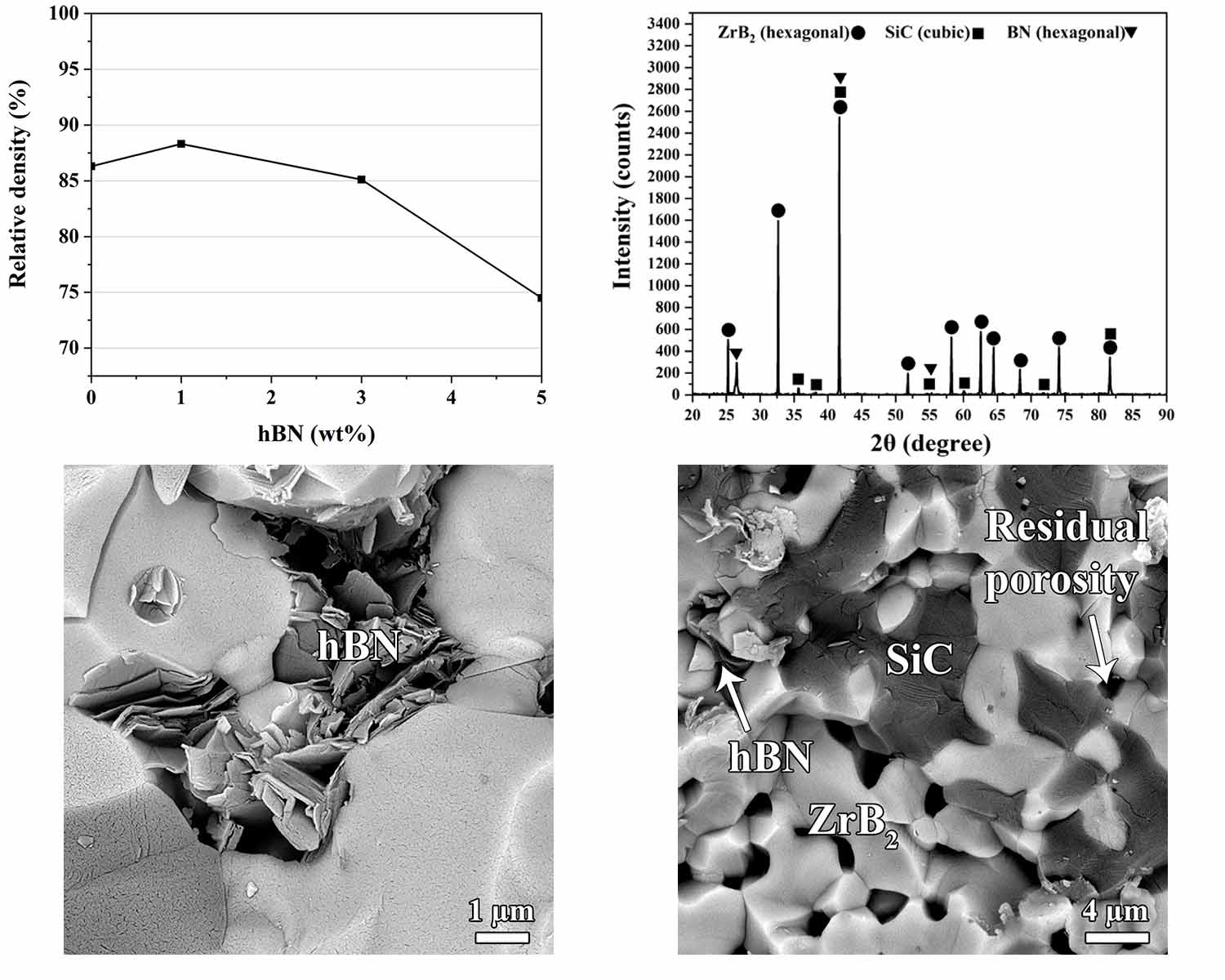

This research is dedicated to investigating the role of different amounts of hexagonal BN (hBN: 0, 1.5, 3, and 4.5 wt%) on the pressureless sinterability of ZrB2–25 vol% SiC ceramics. Phenolic resin (5 wt%) with a carbon yield of ~40% was incorporated as a binder to the powder mixtures and after initial cold pressing, the final sintering process was performed at 1900 °C for 100 min in a vacuum furnace. The as-sintered specimens were characterized by X-ray diffractometry, field emission scanning electron microscopy, and energy-dispersive X-ray spectroscopy. The results disclosed that the incorporation of 1.5 wt% hBN could increase the relative density to ~92%, while the sample with zero hBN content just reached ~81% of full densification. Appropriate hBN content not only facilitated the particle rearrangement during the cold pressing, but also removed the harmful oxide impurities during the final sintering. Nevertheless, the addition of higher amounts of hBN remarkably lessened the densification because of more delamination of the non-reacted hBN flakes and release and entrapment of more gaseous by-products induced by the reacted hBN phases.

Downloads

References

Copyright (c) 2021 Iman FarahBakhsh, Riccarda Antiochia, Ho Won Jang

This work is licensed under a Creative Commons Attribution 4.0 International License.

Copyright

Authors are the copyright holders of their published papers in Synthesis and Sintering, which are simultaneously licensed under a Creative Commons Attribution 4.0 International License. The full details of the license are available at https://creativecommons.org/licenses/by/4.0/.

All papers published open access will be immediately and permanently free for everyone to read, download, copy, distribute, print, search, link to the full-text of papers, crawl them for indexing, pass them as data to software, or use them for any other lawful purpose without any registration obstacles or subscription fees.