Characterization of hot-pressed biodegradable zinc-based nanocomposite implant materials reinforced with 10 wt% Mg, WE43, and AZ91

- 1 Department of Defense Technologies, Kırıkkale University, 71450, Kırıkkale, Turkey

- 2 Department of Metallurgical and Materials Engineering, Gazi University, 06500, Ankara, Turkey

- 3 Department of Metallurgical and Materials Engineering, Kırıkkale University, 71450, Kırıkkale, Turkey

Abstract

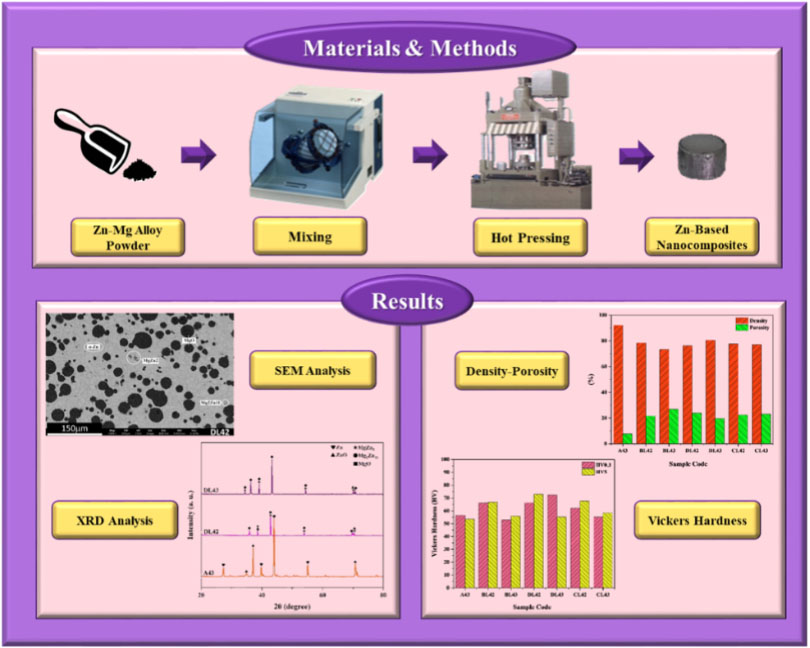

Compared to permanent orthopedic implants for load-bearing applications, biodegradable implants eliminate the necessity for surgical removal after the healing process. Furthermore, magnesium alloy powder reinforced zinc matrix implant materials have been produced to enhance the mechanical properties, biocompatibility, and a proper degradation rate with the growth rate of new bones. This study aims to fabricate Zn-10 wt% Mg, Zn-10 wt% WE43, Zn-10 wt% AZ91, and alloys along with pure Zn sample for control, using the powder metallurgy production method. In this context, hot pressing was applied to samples at 200 °C and 300 °C temperatures, under a constant pressure of 400 MPa to optimize the fabrication parameters. Scanning Electron Microscope (SEM), Energy Dispersive Spectrometry (EDS), Vickers macro- and micro-hardness test (HV), and X-Ray Diffraction Spectroscopy (XRD) analyses were performed to investigate the influence of press temperatures on the microstructure, elemental components, and mechanical properties of the fabricated samples. The microstructures of the zinc matrix nanocomposite samples reinforced with magnesium alloys predominantly consist of MgZn2, Mg2Zn11, and MgO phases dispersed within the refined zinc matrix. The obtained results indicate that Zn Mg alloy nanocomposites hold significant potential as biodegradable orthopedic implant materials; however, it is possible to further improve the properties of the material by optimizing the production parameters.

Downloads

References

Copyright (c) 2025 Onur Fevzi Kevenlik, Shanli Salahi, Yiğit Yalçın, Hanifi Çinici, Recep Çalın

This work is licensed under a Creative Commons Attribution 4.0 International License.

Copyright

Authors are the copyright holders of their published papers in Synthesis and Sintering, which are simultaneously licensed under a Creative Commons Attribution 4.0 International License. The full details of the license are available at https://creativecommons.org/licenses/by/4.0/.

All papers published open access will be immediately and permanently free for everyone to read, download, copy, distribute, print, search, link to the full-text of papers, crawl them for indexing, pass them as data to software, or use them for any other lawful purpose without any registration obstacles or subscription fees.