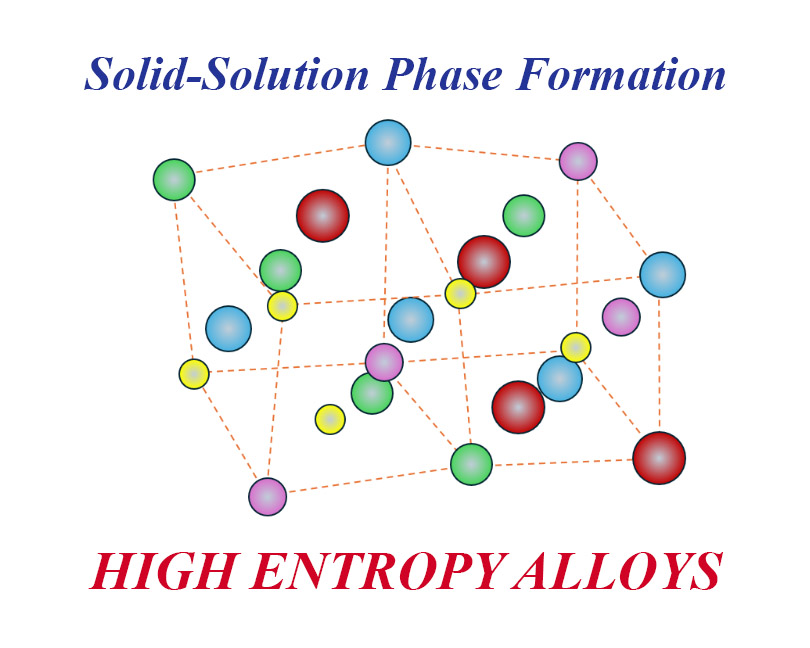

Solid-solution phase formation rules for high entropy alloys: A thermodynamic perspective

- 1 Department of New Science and Technology, Nanomaterials Group, Semnan University, Semnan, Iran

- 2 Department of Materials and Metallurgical Engineering, Semnan University, Semnan, Iran

Abstract

To save time and money before starting the production of a high entropy alloy (HEA), it is important to predict the possibility of HEA formation and the probable final microstructure using the solid solution phase formation thermodynamic rules. In this research, a step-by-step calculation of thermodynamic parameters is conducted to predict the possibility of formation and determine the final properties such as ∆Hmix, ∆Smix, δr, δχ, Ω, VEC, and Tm for three Ni20Co20Cu15Fe20Mn25, Ni35Co20Cu5Fe5Mn35, and Ni5Co5Cu35Fe35Mn20 HEAs. Based on the obtained results, it is not possible to form a HEA with a solid solution structure for the Ni35Co20Cu5Fe5Mn35 and Ni5Co5Cu35Fe35Mn20 systems due to a low ∆Smix value of 11.28 J.mol-1.K-1. Based on the calculated values of ∆Hmix, intermetallic compound formation and segregation are predicted for Ni35Co20Cu5Fe5Mn35 and Ni5Co5Cu35Fe35Mn20, respectively.

Downloads

References

Copyright (c) 2024 Samaneh Mamnooni, Ehsan Borhani, Hassan Heydari

This work is licensed under a Creative Commons Attribution 4.0 International License.

Copyright

Authors are the copyright holders of their published papers in Synthesis and Sintering, which are simultaneously licensed under a Creative Commons Attribution 4.0 International License. The full details of the license are available at https://creativecommons.org/licenses/by/4.0/.

All papers published open access will be immediately and permanently free for everyone to read, download, copy, distribute, print, search, link to the full-text of papers, crawl them for indexing, pass them as data to software, or use them for any other lawful purpose without any registration obstacles or subscription fees.