Investigation of flame retardancy properties of polypropylene-colemanite and intumescent flame retardant additive blends

- 1 Istanbul Technical University, Graduate School of Science, Engineering and Technology, Polymer Science and Technology Department, 34469, Maslak, Istanbul, Türkiye

- 2 Istanbul Technical University, Faculty of Science Department of Chemistryt, 34469, Maslak, Istanbul, Türkiye

Abstract

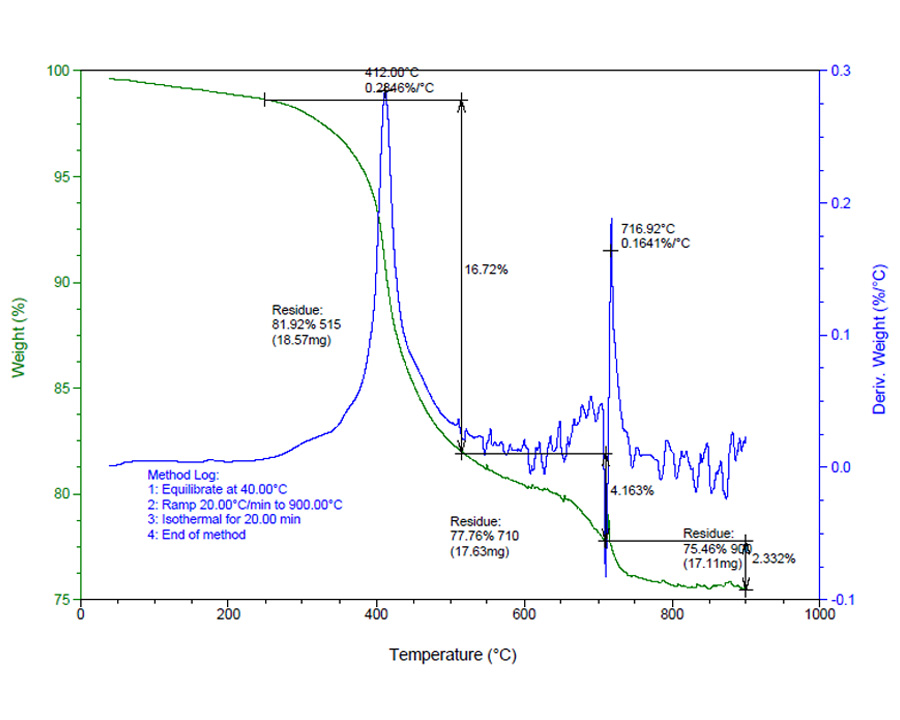

Polypropylene (PP) represents a considerable proportion of polyolefins (PO) used in different industrial applications such as automobile components, textiles, packaging, insulation, medical devices, various housewares, and household appliances due to its efficient cost, desirable mechanical, thermal and electrical properties, easy processability and recyclability. Because of its carbonaceous structure, PP is a highly flammable material with an LOI value of 18 that presents a serious fire hazard. In this research, Intumescent flame retardant (IFR) and colemanite were added to polypropylene to compose 30% of the total mass of the polymeric compounds, and the synergistic effect of colemanite with intumescent flame retardant (IFR) additive in PP was investigated by limiting oxygen index (LOI), glow wire test (GWT), UL-94 test and mechanical properties measurements. The LOI, UL 94 and glow wire test results showed that colemanite had a significant effect on flame retardancy and LOI value which can reach 37.6% with a loading amount of 2 wt% colemanite at the total amount of flame retardant additives kept constant at 30 wt%. Additionally, the PP/IFR compounds passed UL 94 V0 rating and both 750 °C and 850 °C glow wire tests with 2–8 wt% colemanite loading. According to Thermal gravimetric analyses (TGA), the results indicated that colemanite improved the thermal stability of PP/IFR compounds and also promoted the formation of the char layer. When colemanite mineral is added to polypropylene without an IFR system, it has no effect on the flame retardancy properties of polypropylene. When all properties have been taken into consideration, colemanite can be used up to 4 wt% in IFR.

Downloads

References

Copyright (c) 2022 Merve Kahraman, Nilgün Kızılcan

This work is licensed under a Creative Commons Attribution 4.0 International License.

Copyright

Authors are the copyright holders of their published papers in Synthesis and Sintering, which are simultaneously licensed under a Creative Commons Attribution 4.0 International License. The full details of the license are available at https://creativecommons.org/licenses/by/4.0/.

All papers published open access will be immediately and permanently free for everyone to read, download, copy, distribute, print, search, link to the full-text of papers, crawl them for indexing, pass them as data to software, or use them for any other lawful purpose without any registration obstacles or subscription fees.