Experimental investigation and parameter optimization of Cr2O3 atmospheric plasma spray nanocoatings

- 1 Dynamic and Smart Systems Laboratory, Mechanical Industrial and Manufacturing Engineering Department, University of Toledo, OH 43606, USA

- 2 Department of Materials and Metallurgical Engineering, Amirkabir University of Technology, Tehran, Iran

- 3 Materials Engineering Research Center, Malek Ashtar University of Technology, Tehran, Iran

- 4 Materials Engineering Department, Shahid Rajaee Teacher Training University (SRTTU), Tehran, Iran

Abstract

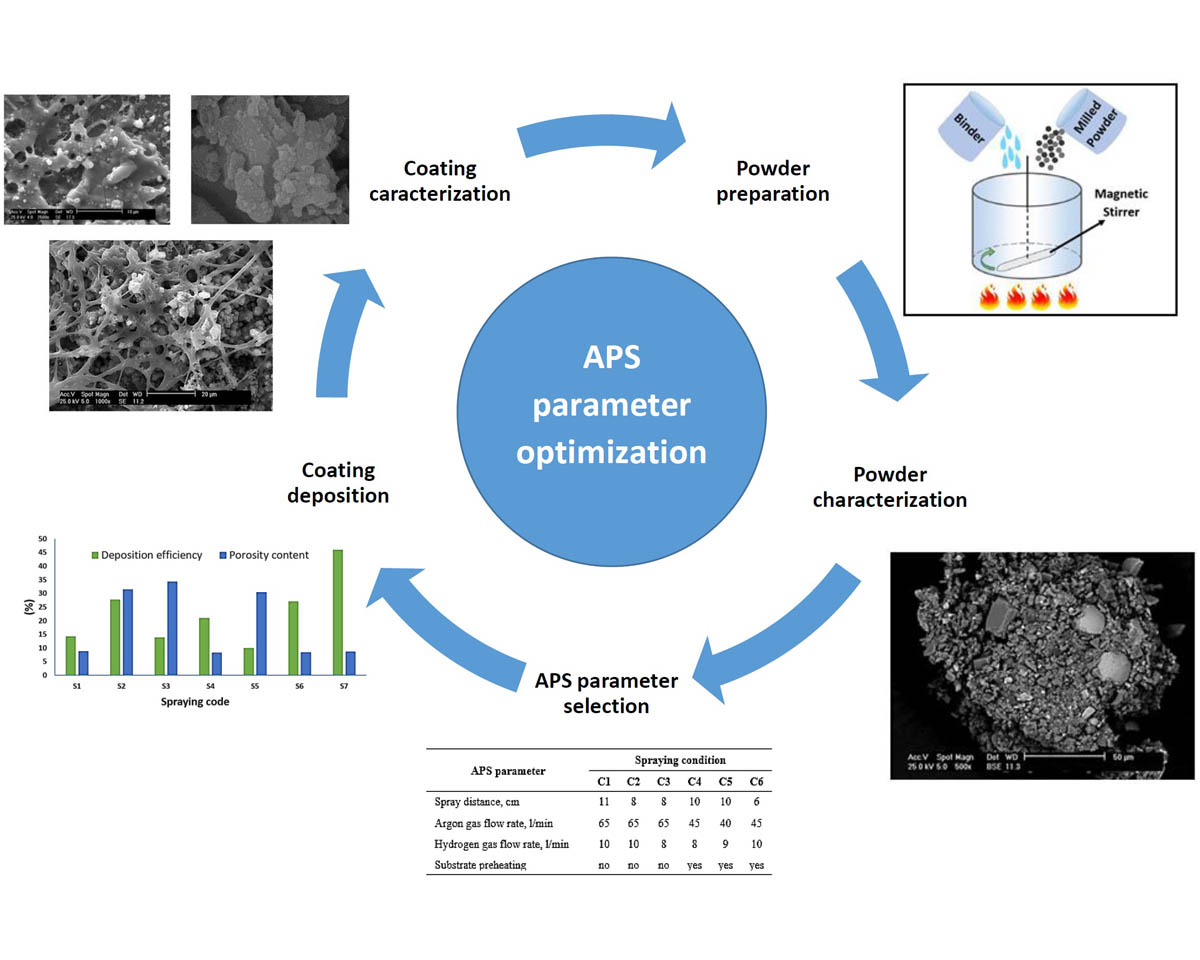

In this research, Cr2O3 ceramic nano-sized powder particles were prepared using ball milling and then were granulated to reach the proper size for spraying. Afterward, Cr2O3 nano-coatings were deposited by atmospheric plasma spraying (APS) process onto stainless steel substrates. To optimize APS parameters, spraying was carried out under six conditions with different parameters. Microstructures of the elemental/milled powder and coatings were characterized via a field emission scanning electron microscope (FESEM) equipped with energy-dispersive spectroscopy (EDS). In this research, Cr2O3 coatings were deposited under different spraying conditions to understand the effect of APS parameters on the splat formation, deposition efficiency, and porosities of the coatings. After parameter optimization, spraying was performed under a high deposition efficiency of 46.0±1.3%. The optimized Cr2O3 coatings showed porosity content, Knoop microhardness, and adhesive strengths of 8.7±2.2%, 823±27 HK0.2, and 49±4 MPa, respectively; making them a good candidate for industrial use.

Downloads

References

Copyright (c) 2021 Seyedmahdi Hashemi, Nader Parvin, Zia Valefi, Soroush Parvizi

This work is licensed under a Creative Commons Attribution 4.0 International License.

Copyright

Authors are the copyright holders of their published papers in Synthesis and Sintering, which are simultaneously licensed under a Creative Commons Attribution 4.0 International License. The full details of the license are available at https://creativecommons.org/licenses/by/4.0/.

All papers published open access will be immediately and permanently free for everyone to read, download, copy, distribute, print, search, link to the full-text of papers, crawl them for indexing, pass them as data to software, or use them for any other lawful purpose without any registration obstacles or subscription fees.