Influence of preheating temperature on splat morphology of spray deposited yttria-stabilized zirconia and lanthanum magnesium hexaaluminate in thermal barrier coatings

- 1 Faculty of Materials and Metallurgical Engineering, Semnan University, Semnan, Iran

- 2 Ceramic Department, Materials and Energy Research Center (MERC), Karaj, Iran

- 3 Department of Materials Engineering, Tarbiat Modares University, Tehran, Iran

- 4 Department of Advanced Materials and New Energies, Iranian Research Organization for Science and Technology (IROST), Tehran, Iran

Abstract

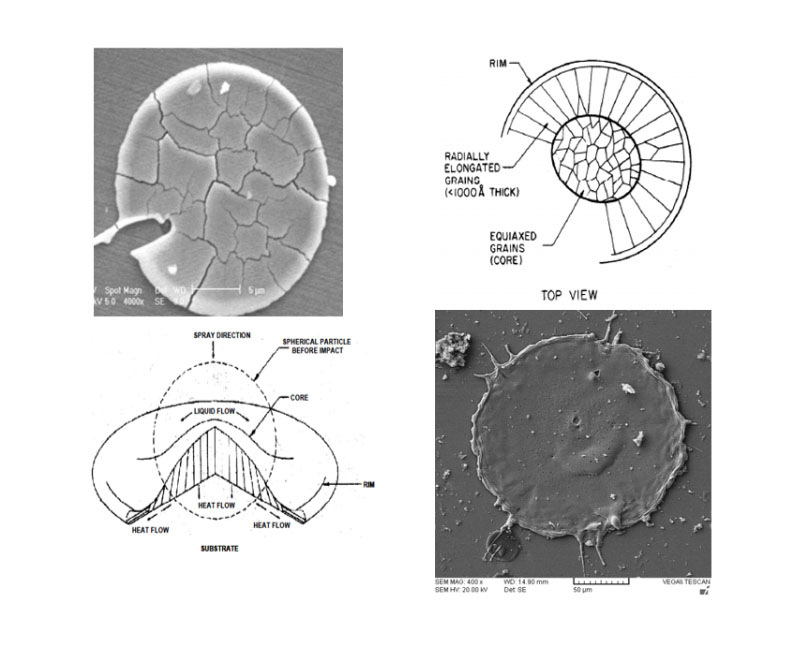

The performance of thermal barrier coatings (TBCs) depends upon the morphology of individual splats and how a single particle flattens. A splat is a single unit cell of thermal barrier coatings. Its properties significantly influence the overall performance of the coating. The transition temperature of the substrate affects the splat morphology and influences the adhesion strength of the applied coating. This study investigates the effect of substrate preheating temperature on splat morphology and the critical transition temperature for yttria-stabilized zirconia (8YSZ) and lanthanum magnesium hexaaluminate (LaMgAl11O19, LaMA) powders deposited via atmospheric plasma spray (APS). Using scanning electron microscopy (SEM), a critical transition temperature of 400 °C was identified for both materials. Disc-shaped splats with improved adhesion formed at this temperature, while irregular shapes were observed below 400 °C, and disordered morphologies appeared above it. Notably, at 400 °C, 8YSZ splats exhibited surface cracks, whereas LaMA splats remained crack-free, highlighting differences in their thermo-mechanical properties. These findings emphasize the importance of optimizing preheating temperature to achieve desirable splat morphology and enhance TBC performance.

Downloads

References

Copyright (c) 2025 Mohammad Mehdi Khorramirad, Mohammad Reza Rahimipour, Mohammad Mehdi Hadavi, Kourosh Shirvani

This work is licensed under a Creative Commons Attribution 4.0 International License.

Copyright

Authors are the copyright holders of their published papers in Synthesis and Sintering, which are simultaneously licensed under a Creative Commons Attribution 4.0 International License. The full details of the license are available at https://creativecommons.org/licenses/by/4.0/.

All papers published open access will be immediately and permanently free for everyone to read, download, copy, distribute, print, search, link to the full-text of papers, crawl them for indexing, pass them as data to software, or use them for any other lawful purpose without any registration obstacles or subscription fees.