Additive manufacturing of AISI 304L stainless steel: A review of processing parameters and mechanical performance

- 1 Department of Materials Engineering, Shahid Bahonar University, Kerman, Iran

- 2 Department of Civil Engineering, Kharazmi University, Tehran, Iran

- 3 Department of Materials Science and Engineering, Sharif University of Technology, P.O. Box 11365-9466, Tehran, Iran

Abstract

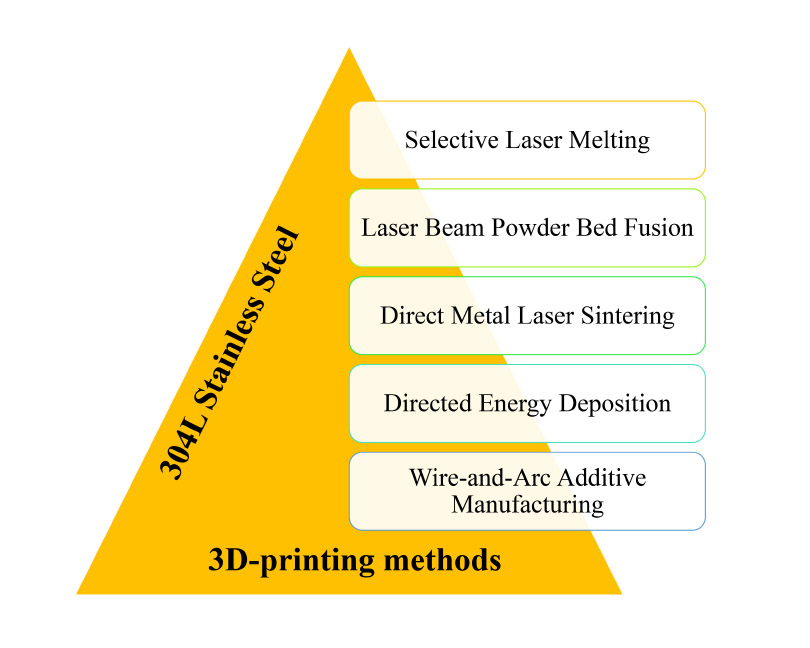

Additive manufacturing (AM) has become a favorable method for producing 304L stainless steel (SS) for various industrial applications, which is owing to its favorable characteristics including corrosion resistance, mechanical performance, and design flexibility. This review paper presents a comprehensive overview of the processing factors along with the mechanical performance of AM-fabricated 304L SS (AM304LSS). Firstly a discussion is provided for the fundamental principles of AM techniques that are common for processing SS304L. This includes selective laser melting (SLM), laser beam powder bed fusion (LB-PBF), direct metal laser sintering (DMLS), directed energy deposition (DED), wire-and-arc additive manufacturing (WAAM). Subsequently, the impact of key processing factors i.e. laser power, and powder characteristics on the microstructure and mechanical properties of AM304LSS is presented. In addition, this article examines recent progress in process optimization strategies and post-processing techniques for improving and enhancing the mechanical properties and surface finish of AM 304L stainless steel components. Finally, significant insights are provided for researchers, engineers, and practitioners involved in the advancement and application of AM304LSS components.

Downloads

References

Copyright (c) 2024 Aliasghar Abouchenari, Mohamad Javad Jalilpour, Mohammad Reza Ahmadpour Yazdi

This work is licensed under a Creative Commons Attribution 4.0 International License.

Copyright

Authors are the copyright holders of their published papers in Synthesis and Sintering, which are simultaneously licensed under a Creative Commons Attribution 4.0 International License. The full details of the license are available at https://creativecommons.org/licenses/by/4.0/.

All papers published open access will be immediately and permanently free for everyone to read, download, copy, distribute, print, search, link to the full-text of papers, crawl them for indexing, pass them as data to software, or use them for any other lawful purpose without any registration obstacles or subscription fees.