Recent advances in machine learning algorithms for sintering processes

- 1 Department of Electrical and Electronic Engineering, Eastern Mediterranean University, Gazimağusa, Mersin 10, Türkiye

Abstract

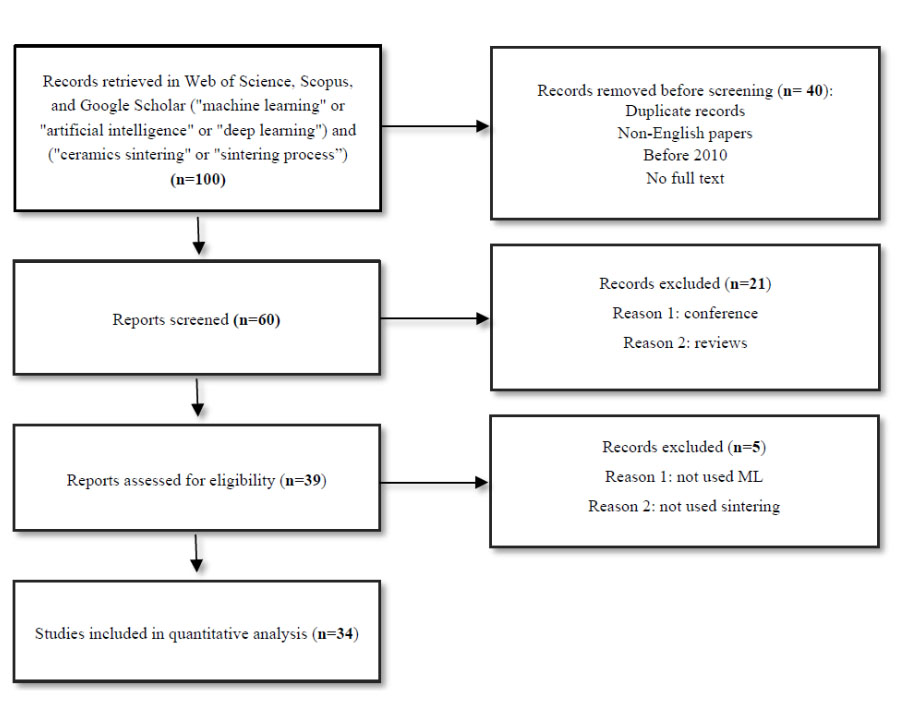

Machine learning (ML) is a fast-growing field that has vast applications in different areas and sintering has had no exemption from that. In this paper, the application of ML methods in sintering of the various materials has been reviewed. Based on our review, it was used to optimize the sintering process and improve the characteristics of the final product. For instance, a supervised learning algorithm was used to predict the temperature and time based on the raw material properties and the desired properties of the final product in sintering. Among all ML methods, k-nearest neighbor (k-NN), random forest (RF), support vector machine (SVM), regression analysis (RA), and artificial neural networks (ANN) had great applications in the sintering field. There are a limited number of papers that used deep learning in sintering. In conclusion, ML methods can be used to optimize sintering process in energy, cost and time.

Downloads

References

Copyright (c) 2023 Shahla Azizi

This work is licensed under a Creative Commons Attribution 4.0 International License.

Copyright

Authors are the copyright holders of their published papers in Synthesis and Sintering, which are simultaneously licensed under a Creative Commons Attribution 4.0 International License. The full details of the license are available at https://creativecommons.org/licenses/by/4.0/.

All papers published open access will be immediately and permanently free for everyone to read, download, copy, distribute, print, search, link to the full-text of papers, crawl them for indexing, pass them as data to software, or use them for any other lawful purpose without any registration obstacles or subscription fees.