Influence of TiN addition on densification behavior and mechanical properties of ZrB2 ceramics

- 1 Department of Aeronautical Engineering, University of Kyrenia, Kyrenia, Cyprus

- 2 Ceramic Department, Materials and Energy Research Center (MERC), Karaj, Iran

Abstract

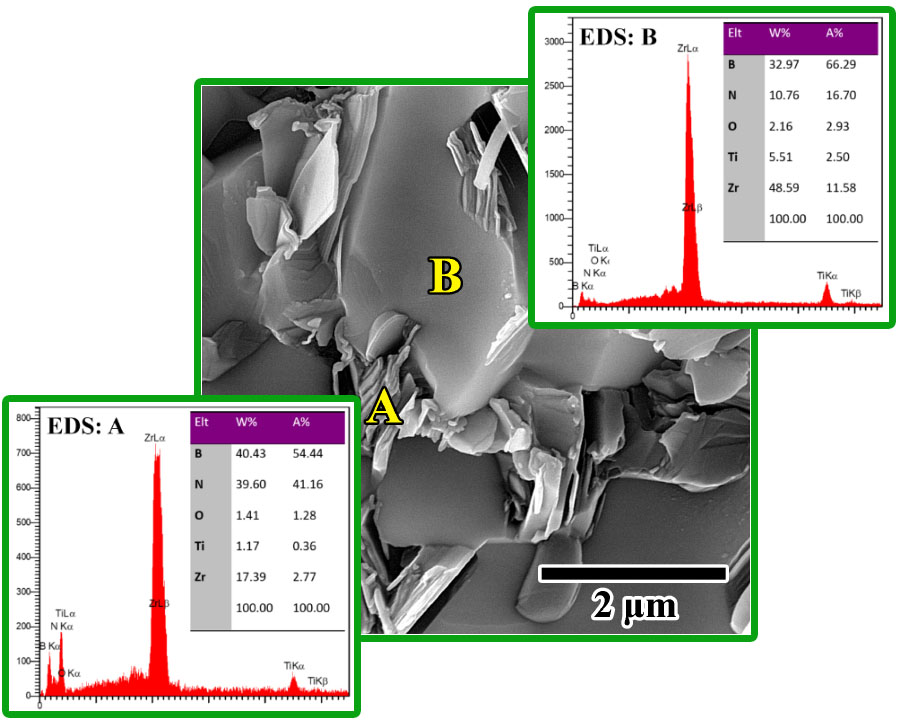

In the present work, densification behavior and mechanical features (fracture toughness and Vickers hardness) of undoped and TiN-doped ZrB2 ceramic materials, hot-pressed at 1800 °C under 15 MPa for 1 h, were studied. The addition of only 5 wt% TiN into ZrB2 has resulted in an increase in its relative density from 83% to 90%. Removal of oxide contaminations like B2O3 via chemical reactions with TiN and new secondary phases formation such as ZrN, h-BN, and (Zr,Ti)B2 solid solutions were approved employing crystalline phase analysis and microstructural studies. Improvement of densification and restriction of grain growth caused enhancement of mechanical characteristics. The measured values of Vickers hardness and fracture toughness are ameliorated from 7.8 GPa and 1.5 MPa.m1/2 to 14.1 GPa and 3.8 MPa.m1/2, respectively.

Downloads

References

Copyright (c) 2023 Alain Shima, Masoud Kazemi

This work is licensed under a Creative Commons Attribution 4.0 International License.

Copyright

Authors are the copyright holders of their published papers in Synthesis and Sintering, which are simultaneously licensed under a Creative Commons Attribution 4.0 International License. The full details of the license are available at https://creativecommons.org/licenses/by/4.0/.

All papers published open access will be immediately and permanently free for everyone to read, download, copy, distribute, print, search, link to the full-text of papers, crawl them for indexing, pass them as data to software, or use them for any other lawful purpose without any registration obstacles or subscription fees.