Pulsed electric current sintering of TiB2-based ceramics using nitride additives

- 1 Koç University Boron and Advanced Materials Applications and Research Center (KUBAM), Sariyer, Istanbul, 34450, Turkey

- 2 Department of Biophysics, Istanbul University-Cerrahpasa, Istanbul, Turkey

- 3 Department of Geophysical Engineering, Istanbul Technical University, Istanbul, Turkey

- 4 Advanced Nano Surface Department, Korea Institute of Materials Science, Changwon, 51508, Republic of Korea

- 5 Department of Materials Science and Engineering, Research Institute of Advanced Materials, Seoul National University, Seoul 08826, Republic of Korea

- 6 Innovative Enterprise Cooperation Center, Korea Institute of Science & Technology, Hwarangro 14-gil, Seongbuk-gu, Seoul 02792, Republic of Korea

Abstract

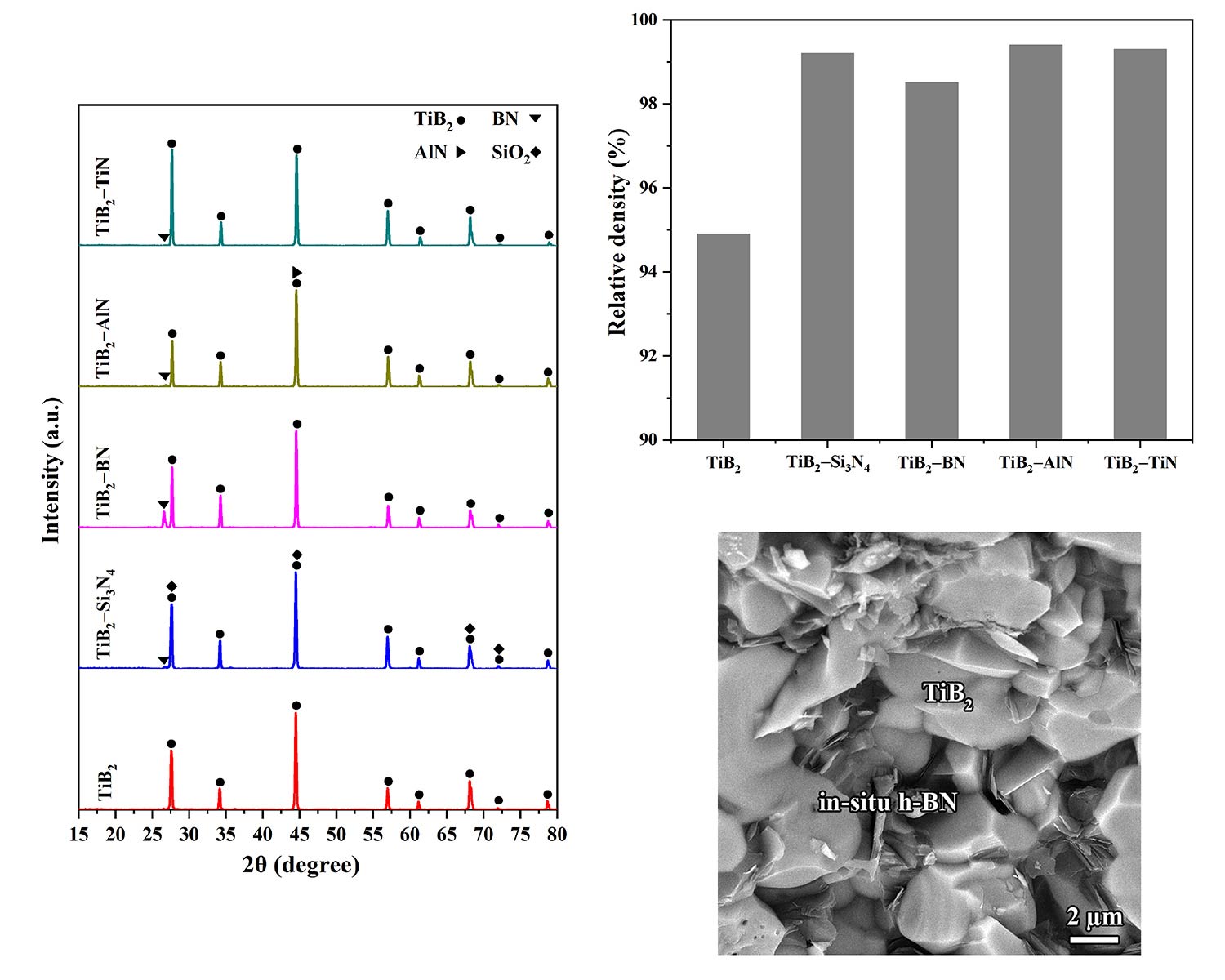

In this research, various types of nitride additives were incorporated into titanium diboride attaining dense TiB2-based ceramics by field-assisted sintering technique. The addition of different types of nitride additives, namely Si3N4, BN, AlN, and TiN, significantly improved the sinterability of TiB2, achieving near fully dense ceramics. The X-ray diffraction analysis and microstructural evaluation confirmed the presence of the h-BN compound in all specimens. In the TiB2-Si3N4 ceramic, Si3N4 additive reacted with B2O3 oxide, in-situ generating h-BN, and SiO2 phases. Although the h-BN phase was produced in the TiB2-AlN specimen, the main proportion of AlN remained in the sample as an unreacted ex-situ phase. In terms of the TiB2-TiN ceramic, some of the nitrogen and boron atoms could leave the TiN and TiB2 crystalline structures, contributing to the in-situ formation of h-BN.

Downloads

References

Copyright (c) 2021 Naeimeh Sadat Peighambardoust, Çağın Çevik, Tannaz Assar, Sunghoon Jung, Seon Yong Lee, Joo Hwan Cha

This work is licensed under a Creative Commons Attribution 4.0 International License.

Copyright

Authors are the copyright holders of their published papers in Synthesis and Sintering, which are simultaneously licensed under a Creative Commons Attribution 4.0 International License. The full details of the license are available at https://creativecommons.org/licenses/by/4.0/.

All papers published open access will be immediately and permanently free for everyone to read, download, copy, distribute, print, search, link to the full-text of papers, crawl them for indexing, pass them as data to software, or use them for any other lawful purpose without any registration obstacles or subscription fees.