Examination of water uptake performance and mechanical properties of PLA/flax fiber biocomposites with the coupling agent

- 1 Hakkari University, Department of Mechanical Engineering, Hakkari, Türkiye

- 2 Yildiz Technical University, Department of Mechanical Engineering, Istanbul, Türkiye

- 3 Istanbul Technical University, Department of Mechanical Engineering, Istanbul, Türkiye

- 4 Yeditepe University, Department of Materials Science and Nanotechnology Engineering, Istanbul, Türkiye

Abstract

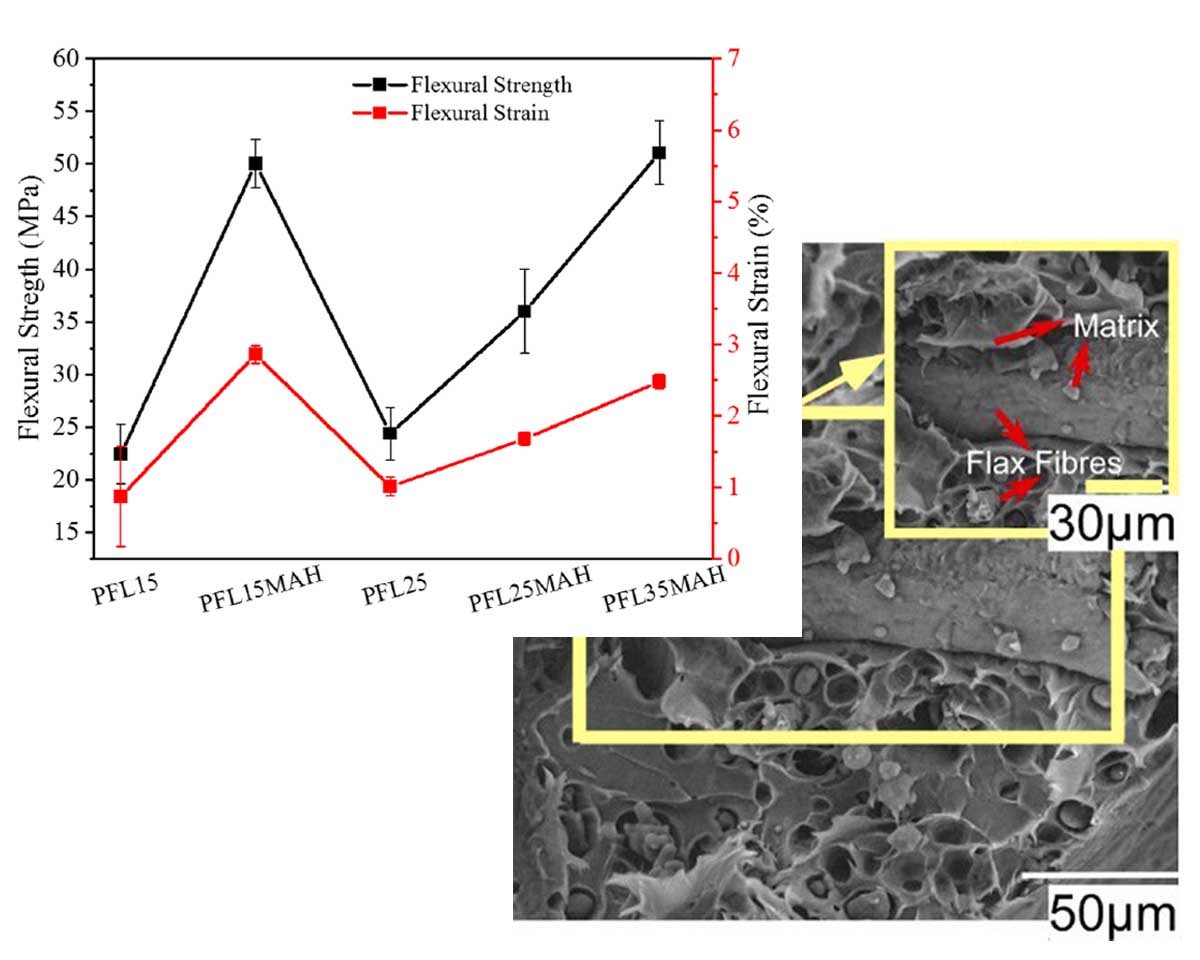

This paper studies the effects of water sorption on the microstructural and flexural properties of the flax fiber/polylactic acid (PLA) biocomposites, compared to the composites with maleic anhydride (MAH) as coupling agents and alkali treatment. Five different biocomposites were prepared: 15 wt% and 25 wt% flax/PLA as the control group, and 15 wt%, 25 wt%, and 35 wt% flax/PLA with 5 wt% MAH. Ten various soaking times were selected to understand the water absorption behavior of the biocomposites. To investigate the mechanical properties of the biocomposites, impact tests were applied on the dry sample as well as the composites with 750-h and 1850-h water sorption. A three-point bending test was performed on the dry and 1850-h water sorption biocomposites to determine their flexural strength. Short flax fiber-reinforced PLA matrix biocomposites were compounded using extrusion and manufactured by injection molding. The flax fiber surface was treated using sodium hydroxy solution to advance the interface interaction between the fiber matrix and surface performance of the fiber and matrix. According to the results, alkali treatment improved the water gain resistance of the composites due to the enhancement of the interfacial bonding. The alkali-treated composites with maleic anhydride showed better impact and flexural strength than the composites without alkali-treated after 1850-h water sorption.

Downloads

References

Copyright (c) 2022 Ali Avci, Aysegul Akdogan Eker, Mustafa Bakkal, Mehmet Safa Bodur

This work is licensed under a Creative Commons Attribution 4.0 International License.

Copyright

Authors are the copyright holders of their published papers in Synthesis and Sintering, which are simultaneously licensed under a Creative Commons Attribution 4.0 International License. The full details of the license are available at https://creativecommons.org/licenses/by/4.0/.

All papers published open access will be immediately and permanently free for everyone to read, download, copy, distribute, print, search, link to the full-text of papers, crawl them for indexing, pass them as data to software, or use them for any other lawful purpose without any registration obstacles or subscription fees.